Wearable / Medical Electronics

Wearable electronics have played a huge role in the growth of Cavist the last three years; and as the intersection of medical and wearable electronics grows less distinct, Cavist has added cleanroom manufacturing and ISO 13485 certification.

A Widened Focus

“Our core focus in overmolding electronics used to be solutions for automotive and industrial applications,” says Page Bailey, Director of Engineering at Cavist. “These markets are still a big opportunity for us, but there’s no denying the growth that we are seeing in the medical and wearables space. We’ve spent significant time developing novel material solutions for overmolding wearable products, and now we have the infrastructure and quality system to support these customers, at scale.”

Demand Drives Development

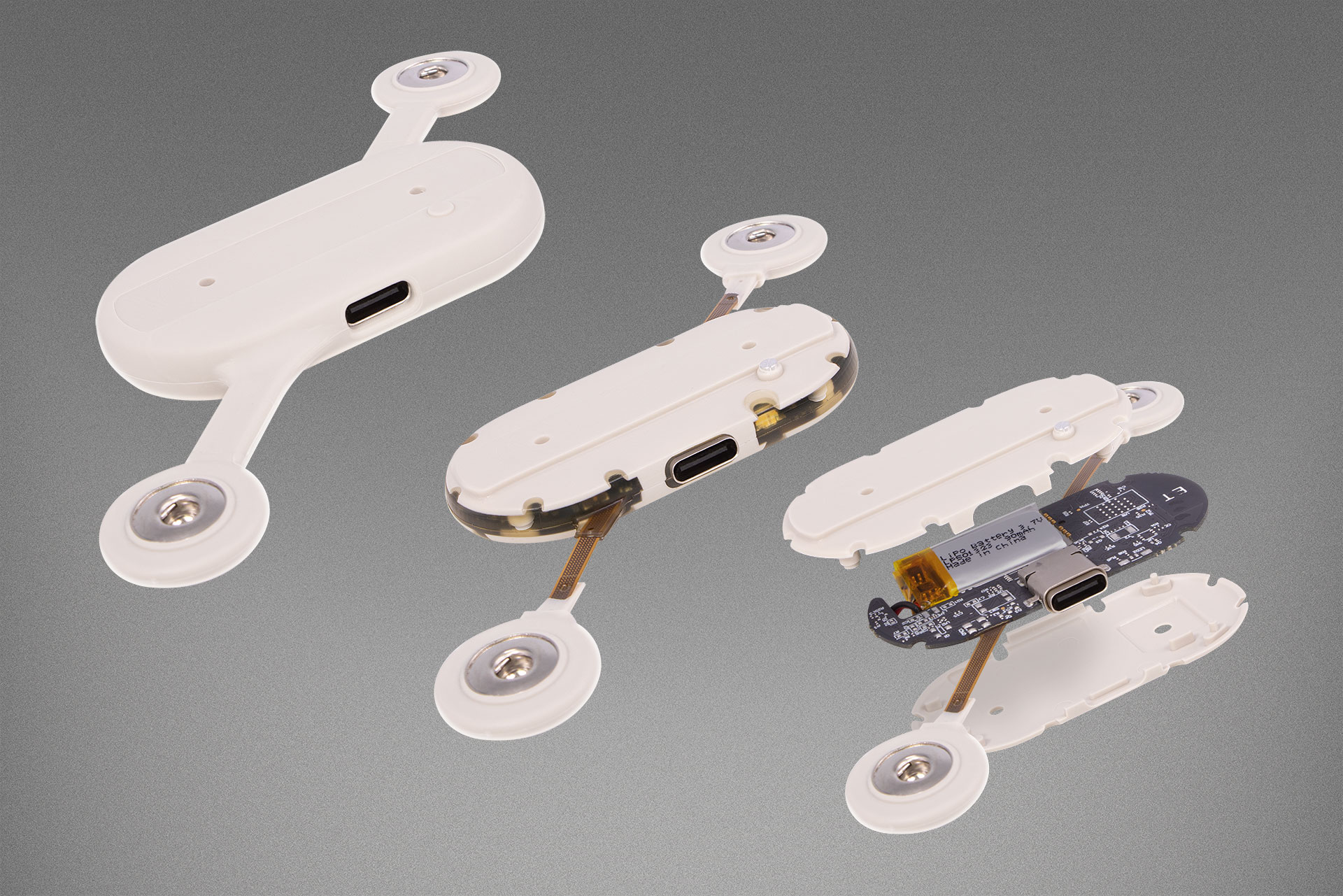

As wearable products become more pervasive in everyday life, there’s increasing demand to reduce the size of the package, while ensuring it is rugged enough to withstand everyday exposure. Overmolding can solve many of the challenges associated with packaging a wearable or medical diagnostic product. By encapsulating the electronic package, the delicate circuit board and sensors are secured against mechanical shock and impact. Overmolding also provides more robust ingress protection than an ultrasonically welded plastic housing. Lastly, Cavist has devised several novel molding approaches for medical wearables, including the use of biocompatible, medical-grade TPE materials.

Cleanroom Expansion

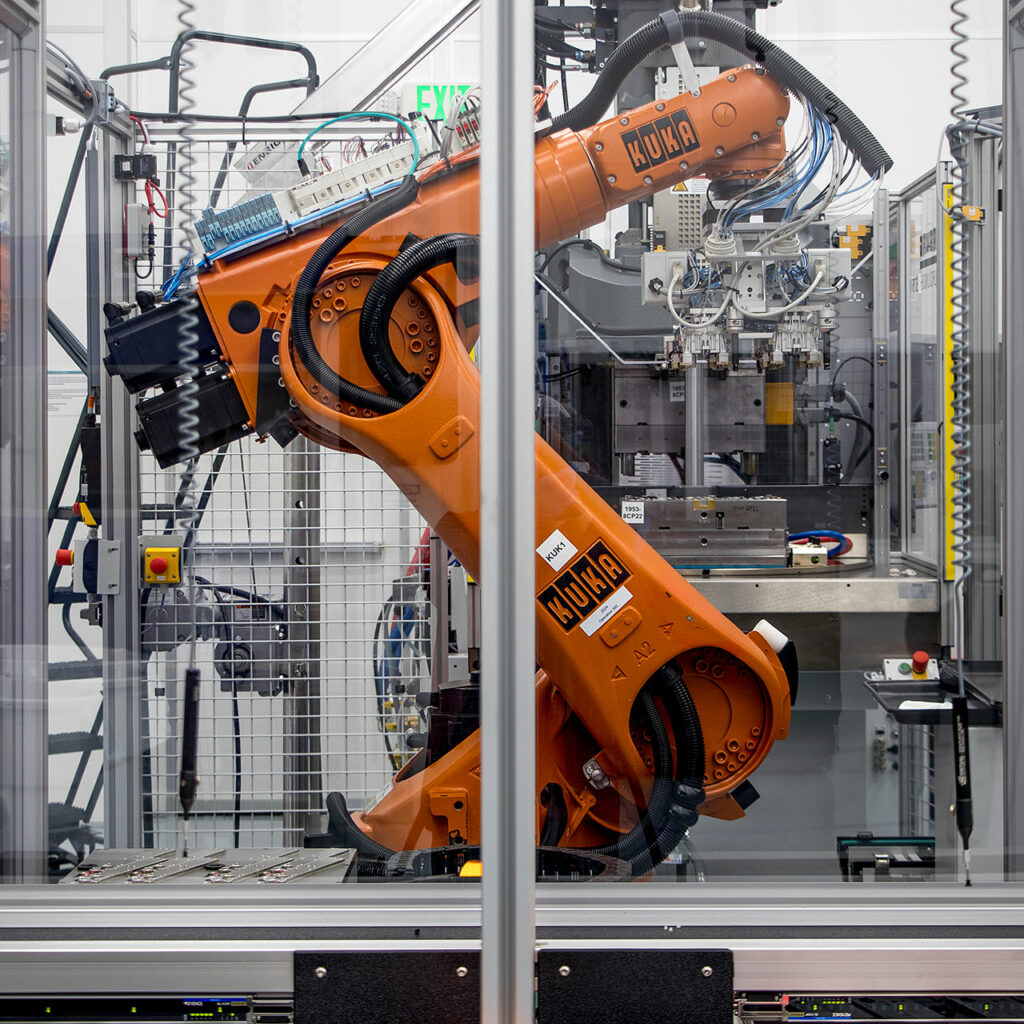

Cavist has installed over 5,000 square feet of ISO Class 100,000 cleanroom space dedicated to overmolding medical electronics in high volume. The addition of the ISO 13485 certification bolsters their strong commitment to quality. At Cavist, the focus is on the future. By listening to the customers’ wants and needs, Cavist continues to innovate and come up with unique solutions that propel the business forward.Reach out to Cavist to get more information about this technology. We would be happy to help you design your way out of any epoxy potting application!