US Tech Magazine

Cavist Takes the Spotlight in the Latest Edition

Easy Engineering Magazine

Interview Featuring Peter Olisa

Electronic Encapsulation Methods, Process and Benefits

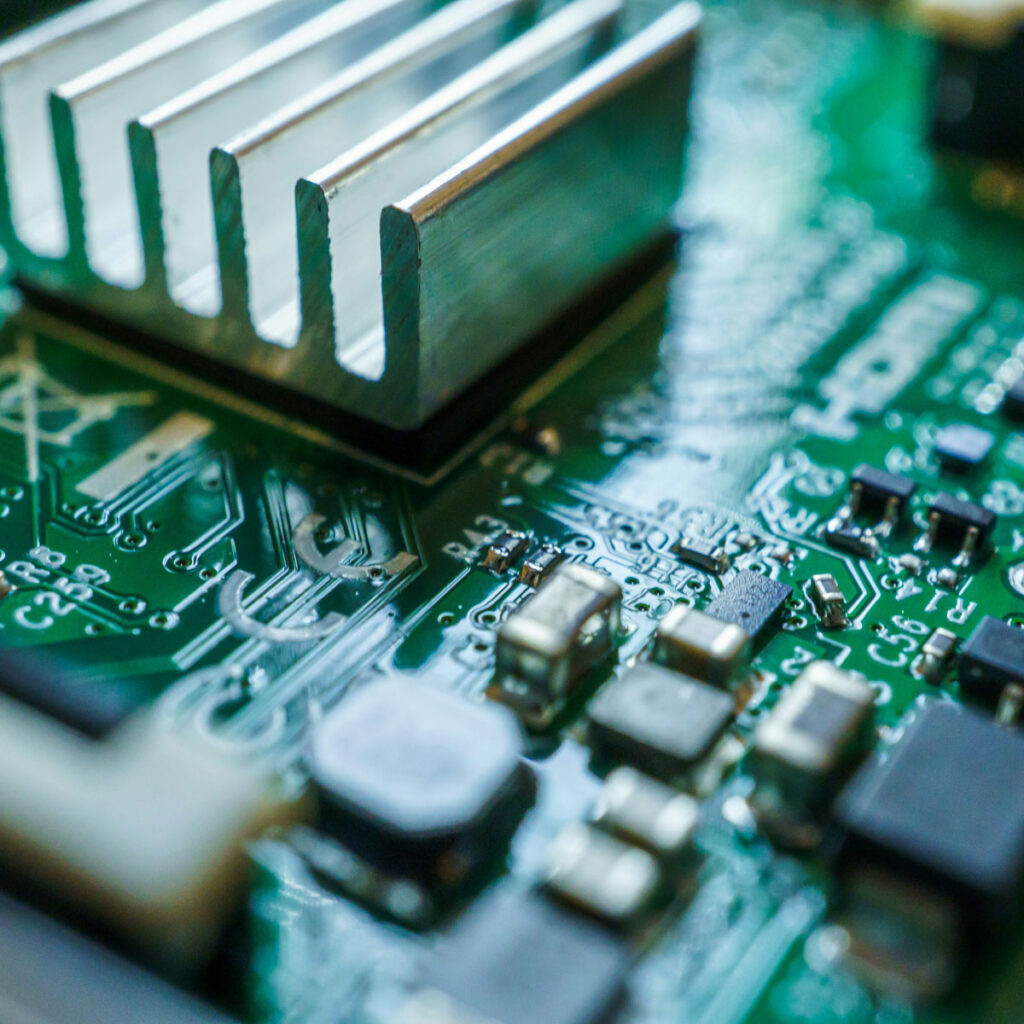

The Future is Electronic As a result, the world is producing the biggest array of electrical components in history. Parts like sensors, actuators, CPUs, and PCBs all need protection against damaging environmental factors like dirt, moisture, heat, and chemical exposure. Electronic encapsulation is a transformative packaging technique that protects electronics from these issues while making […]

MD&M West 2025

February 4-6, 2025 | Anaheim, CA

BIOMEDevice Silicon Valley

November 20-21, 2024 | Santa Clara, CA

MD&M Minneapolis

October 16-17, 2024 | Minneapolis, MN

The Battery Show

October 7-10, 2024 | Detroit, MI

Sensors Converge Expo

June 24-26, 2024 | Santa Clara, CA

DeviceTalks Boston 2024

May 1-2, 2024 | Boston, MA

Cavist is Now Employee Owned

Nothing says customer care quite like ownership.