Vision-to-Volume Statement

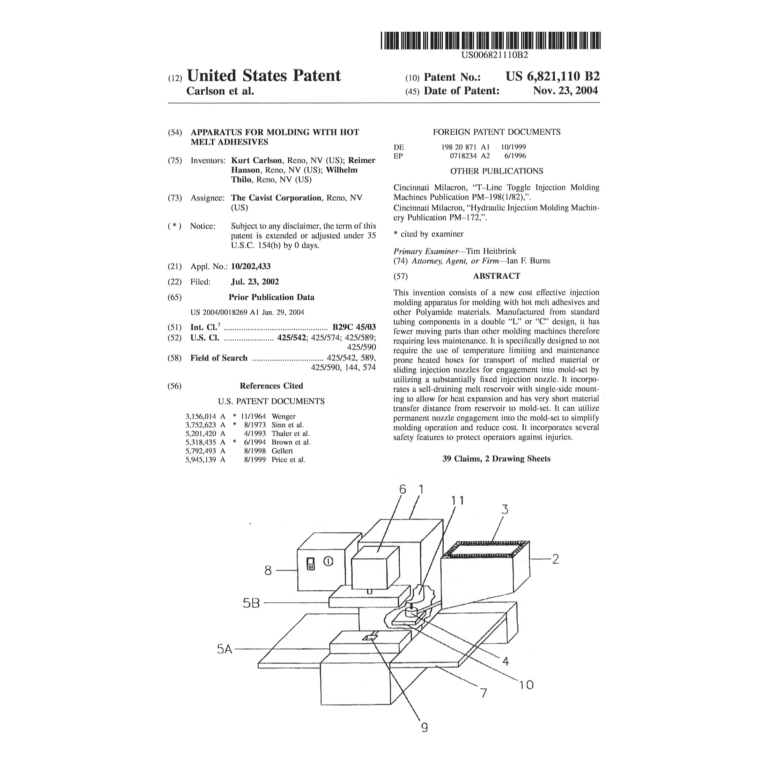

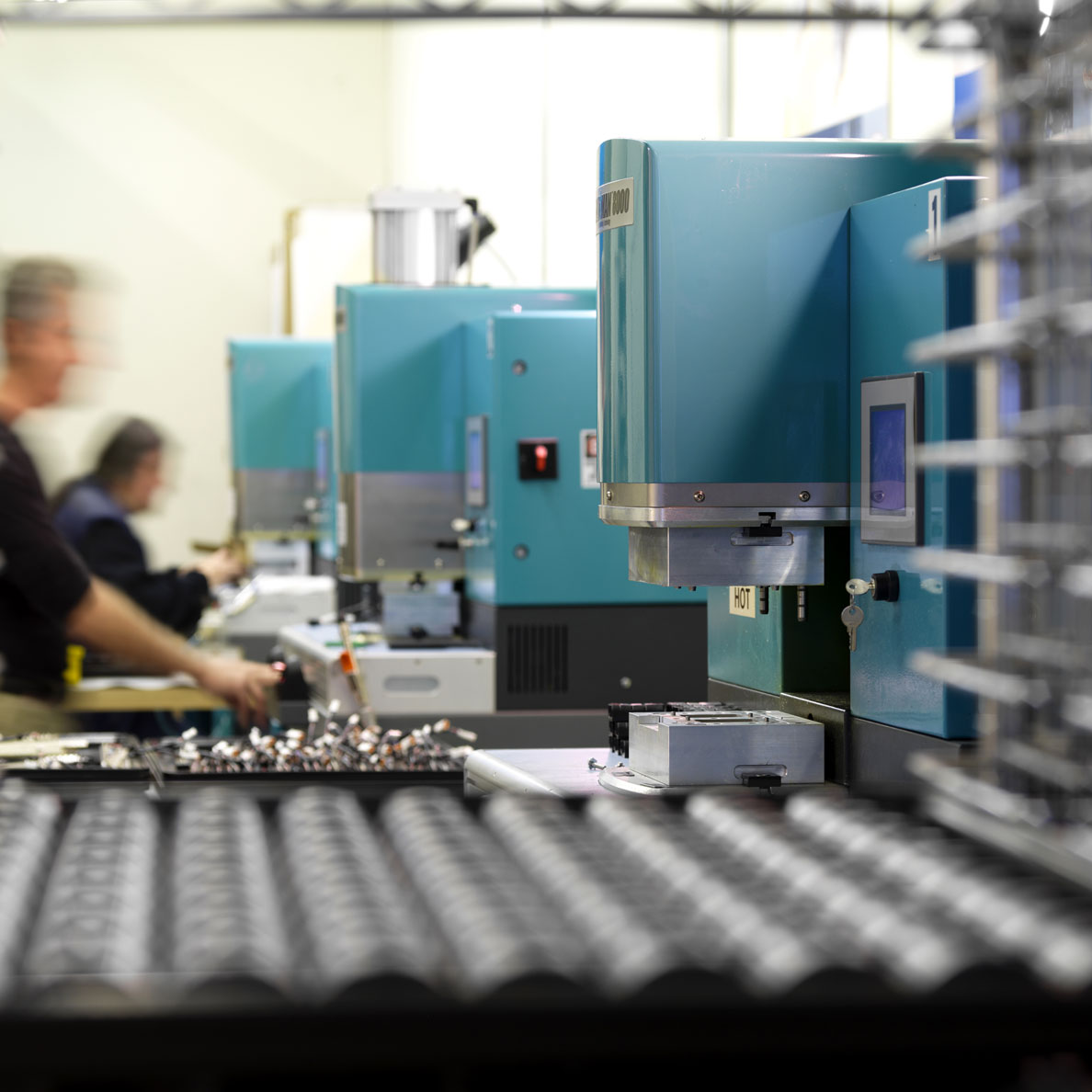

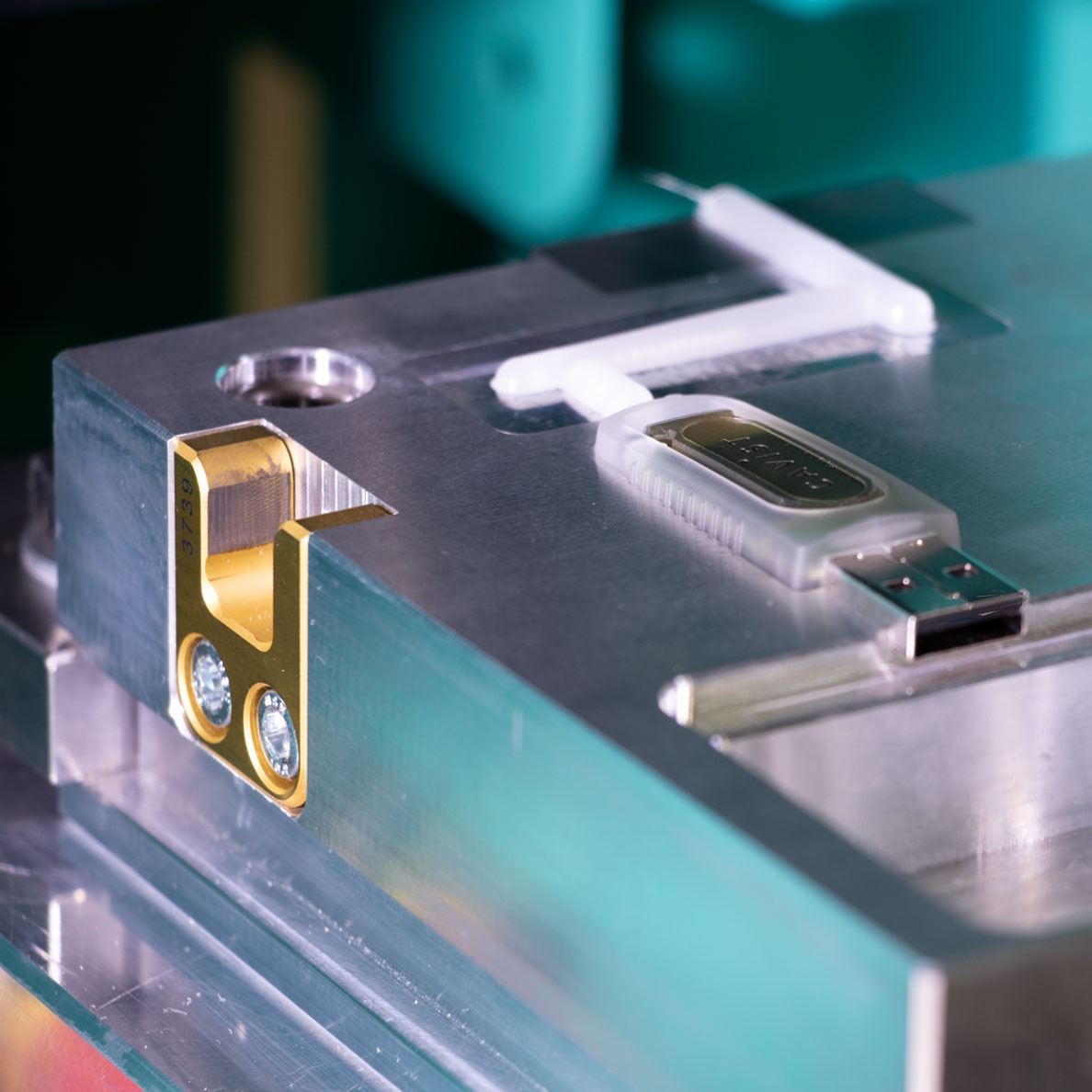

Cavist is a contract manufacturer specializing in sealing and protecting electronics via low pressure injection molding technology, and other means, appropriately. Our primary goal is to determine the best way to encapsulate your electronic assembly, and scale that into volume manufacturing, here at Cavist.