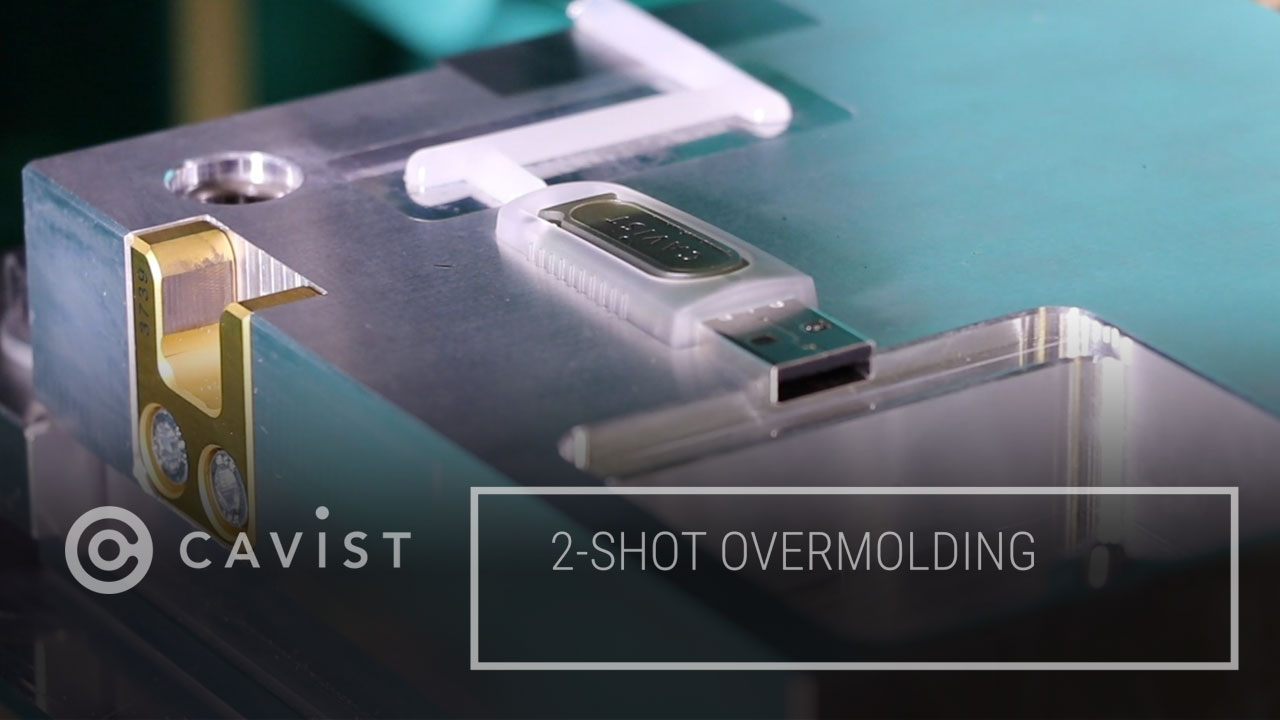

What is 2-Shot Overmolding?

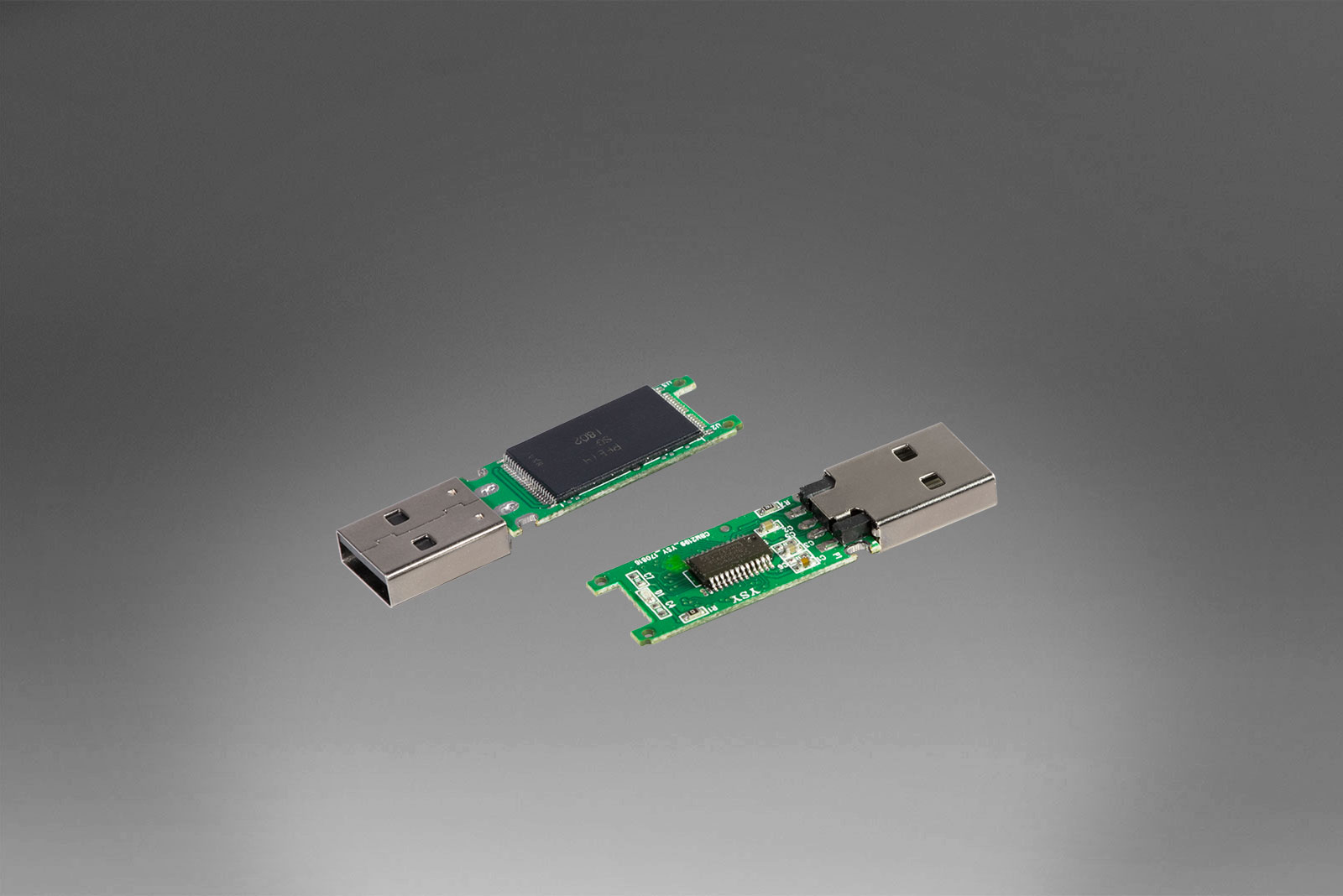

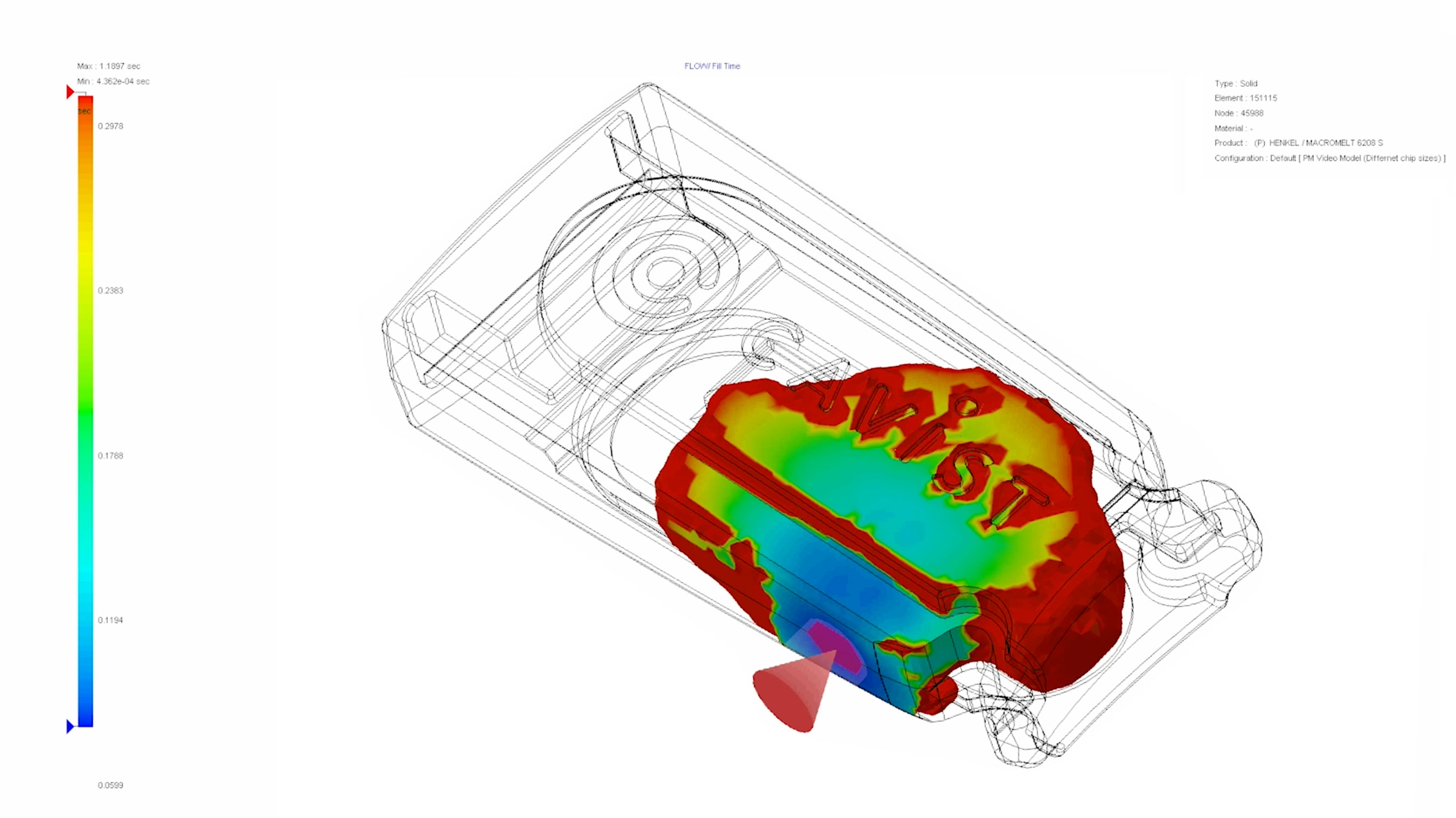

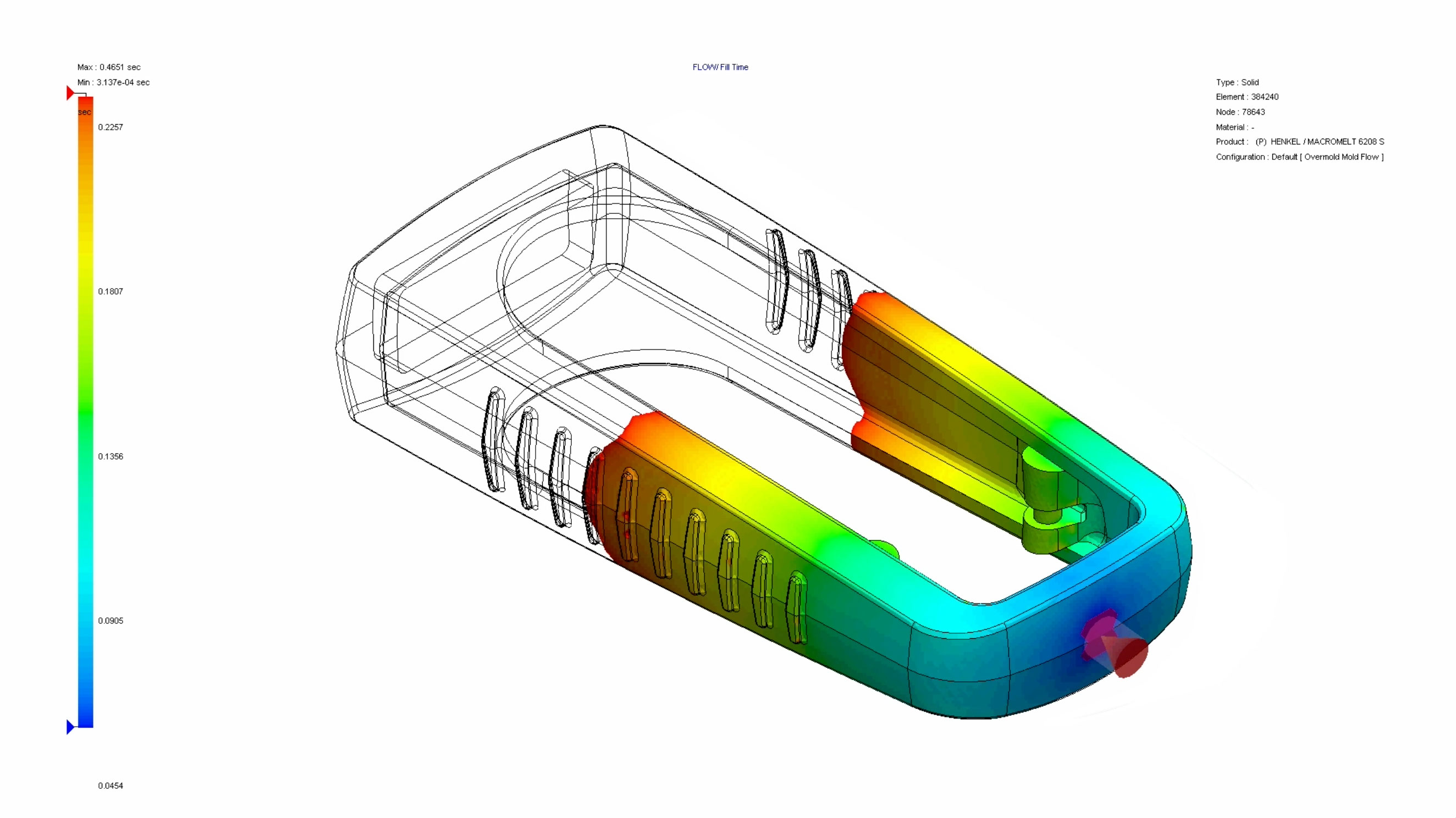

2-Shot Overmolding is any process where one material is injection molded over a previously injection molded substrate. In our case, we are premolding the electronics with LPM, and overmolding with a more durable engineering thermoplastic. This approach yields molded electronics with superior abrasion and chemical resistance, biocompatibility, and more.