Cavist Overmolding Videos

Cavist overmolds delicate electronics in our 30,000 square foot facility in Reno, Nevada, USA. These videos demonstrate a small part of our capabilities in overmolding with Polyamides and 2-Shot materials as well as automation in contract manufacturing and moldflow analysis.

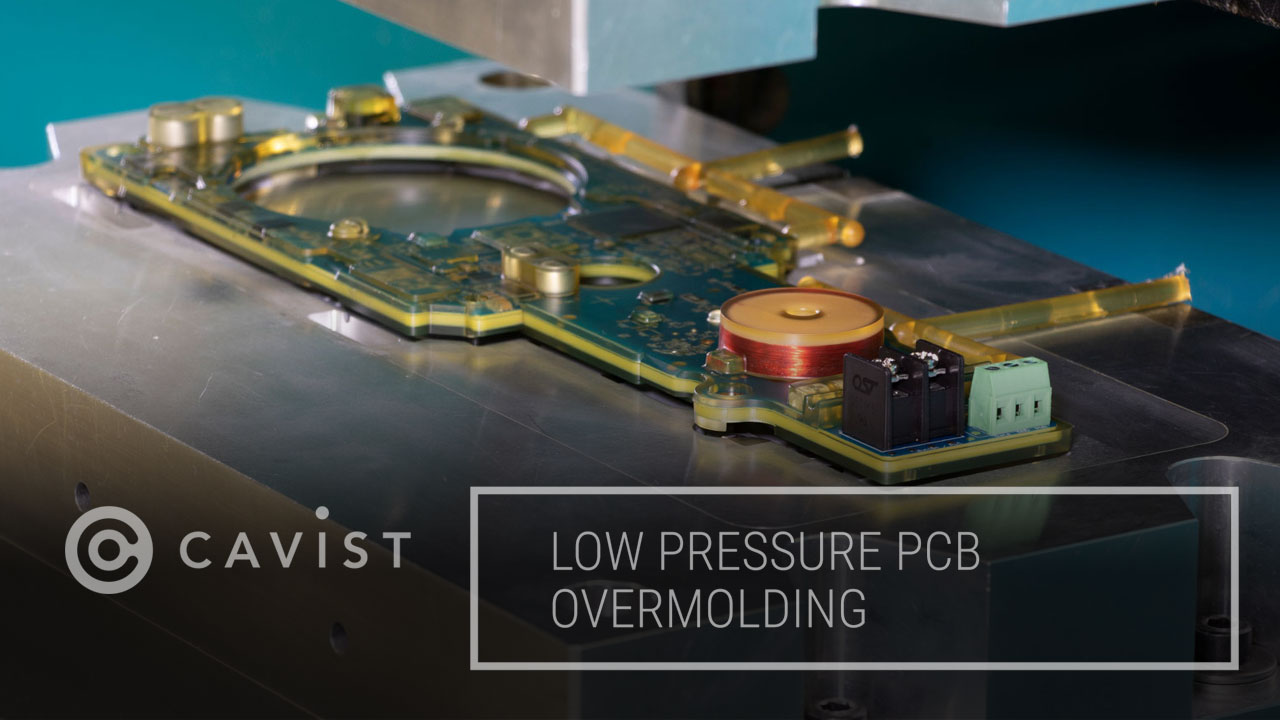

Cavist Low Pressure PCB Overmolding

Cavist overmolds complex circuitry, encapsulating delicate electronic components including batteries, super capacitors, optical sensors and more.

Cavist PCB Plasma Treatment

Cavist uses open air plasma treatment on a printed circuit board (PCB) to promote adhesion during subsequent overmolding process.

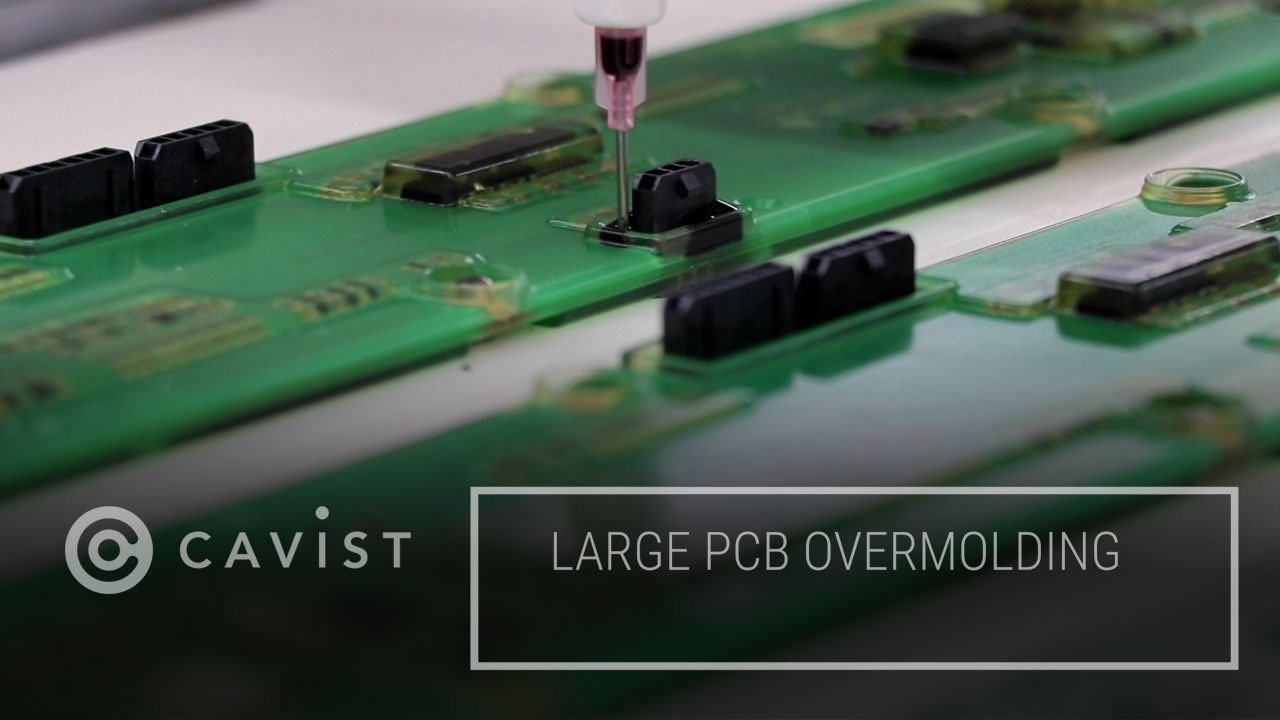

Cavist large PCB overmolding with automated epoxy dispense

Cavist encapsulates a large printed circuit board (PCB) with low pressure molding and uses automated dispensing equipment to seal connectors with epoxy potting.

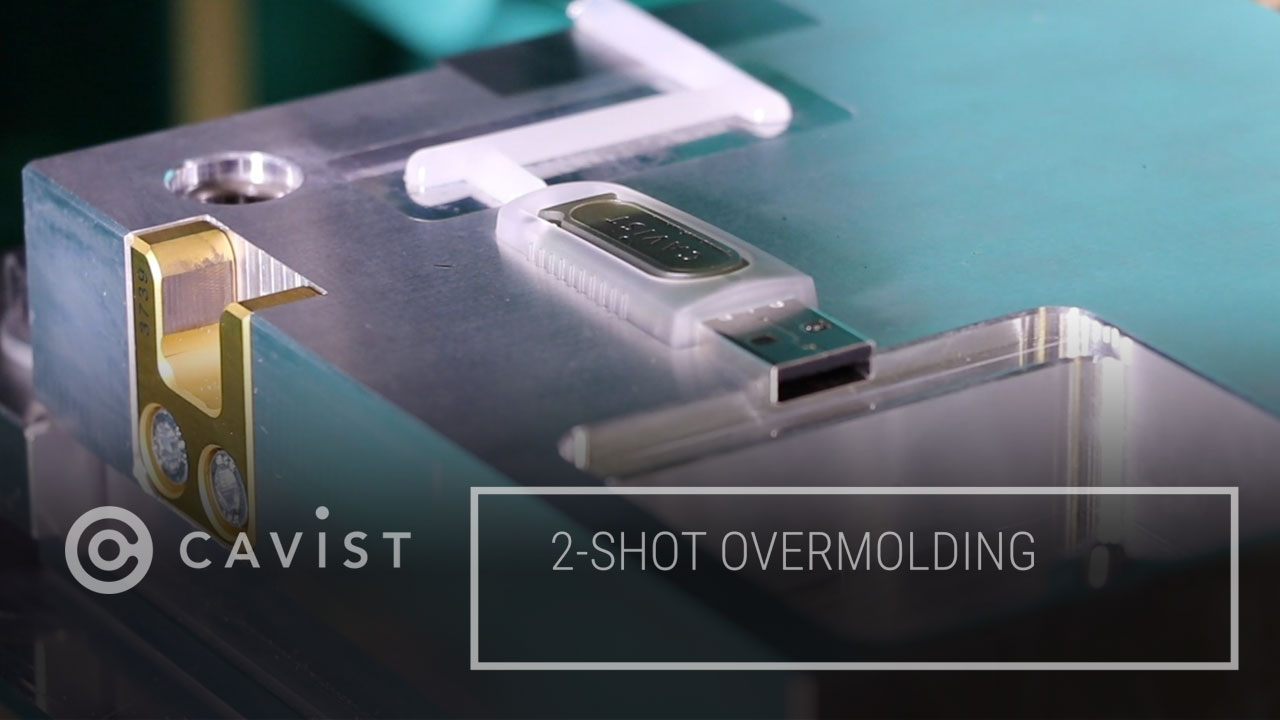

Cavist 2-Shot Overmolding:

Wearable Electronics

Cavist encapsulates delicate electronics at low temperature and pressure, followed by an overmolded durable outer layer for form and protection.

Cavist 2-Shot PCB Overmolding

Cavist encapsulates delicate electronics at low temperature and pressure, followed by an overmolded durable exterior for chemical resistance, abrasion resistance and UV stability.

Cavist Assembly Automation

Cavist integrates automation into assembly and overmolding for high volume applications.

Cavist Moldflow Analysis Videos

Prior to overmolding sensitive electronics, PCBs, connectors and cable assemblies, Cavist performs a moldflow analysis to anticipate and guide the flow of material around the components with regards to volume, temperature, flow and cooling. Moldflow Analysis gives us the insight and confirmation needed for efficient and accurate contract manufacturing of sealed electronics.

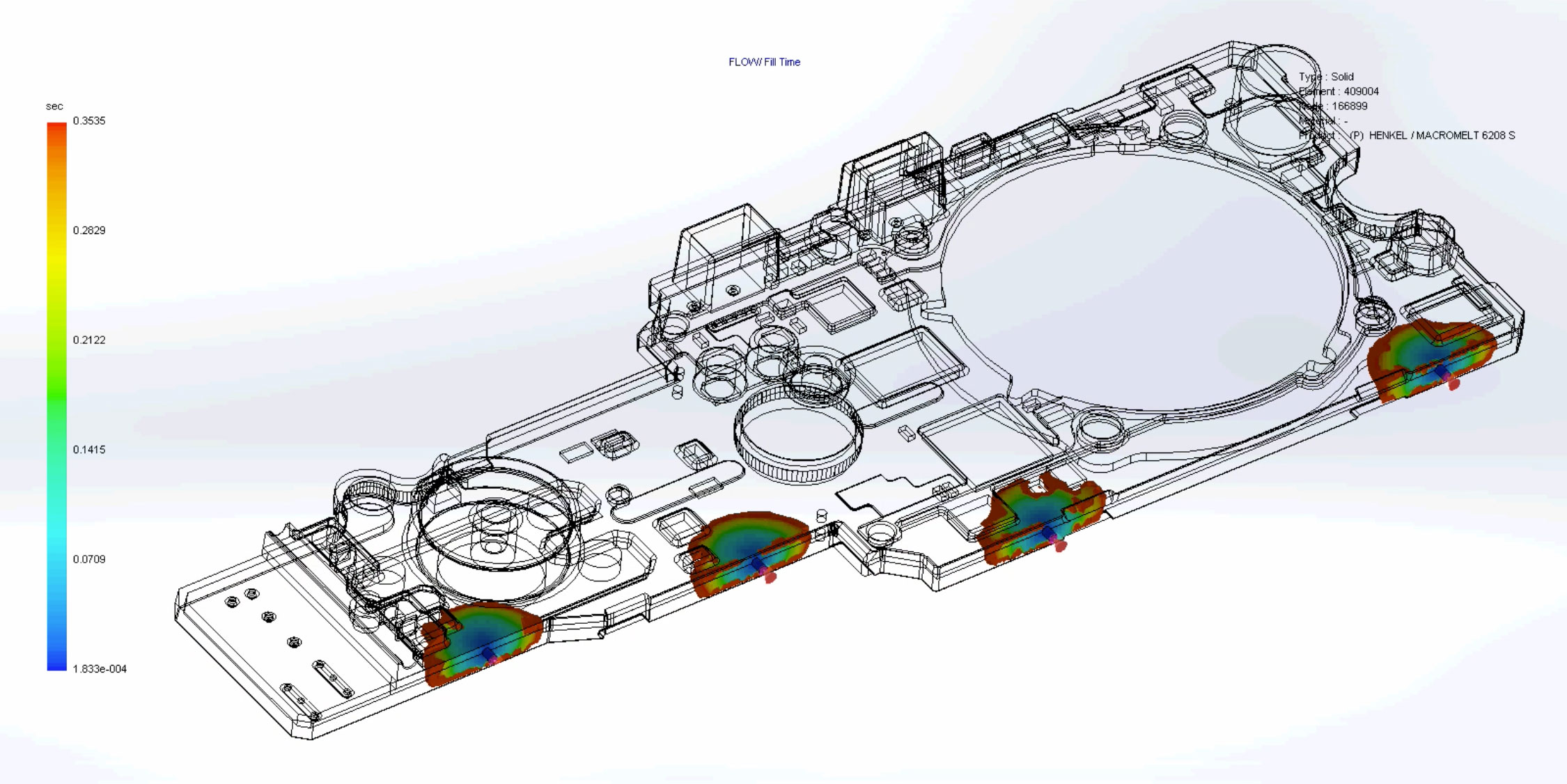

Moldflow Analysis:

Low Pressure Molding PCB

Moldflow analysis for this PCB measuring approximately 11″ x 5″ shows the flow of Technomelt™ Polyamide Low Pressure Molding material as it enters the cavity, flows gently around the printed circuit board (PCB) assembly, as well as the cooling of the material as it completes the process.

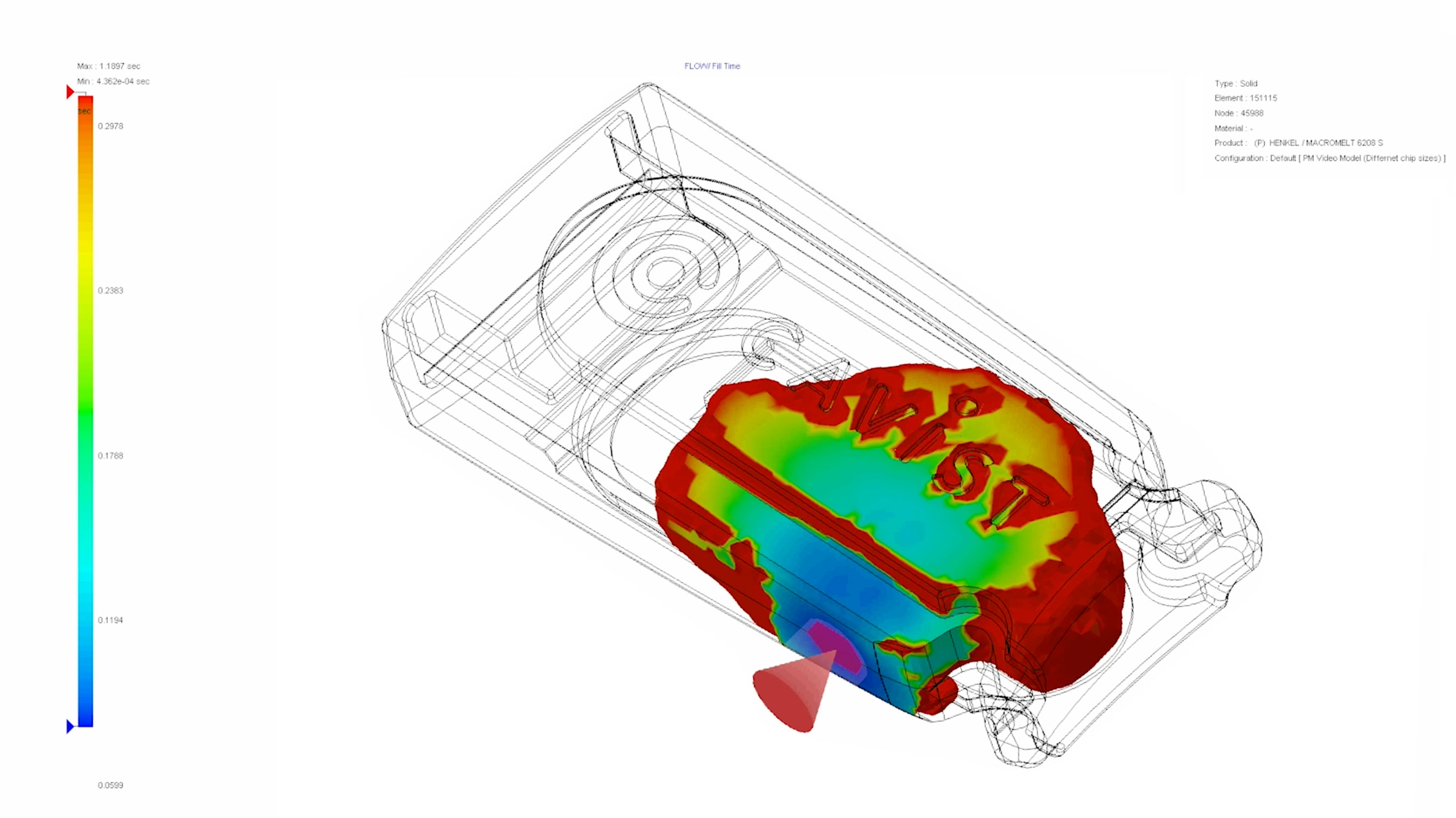

Moldflow Analysis

2-Shot Overmolding [ Shot 1 ]

This is step 1 of the Cavist 2-Shot Overmolding process as seen through Moldflow Analysis. This USB thumb drive with PCB and LED is gently encapsulated with Technomelt™ Polyamide material for protection of the electronics from temperature, impact, dust and vibration.

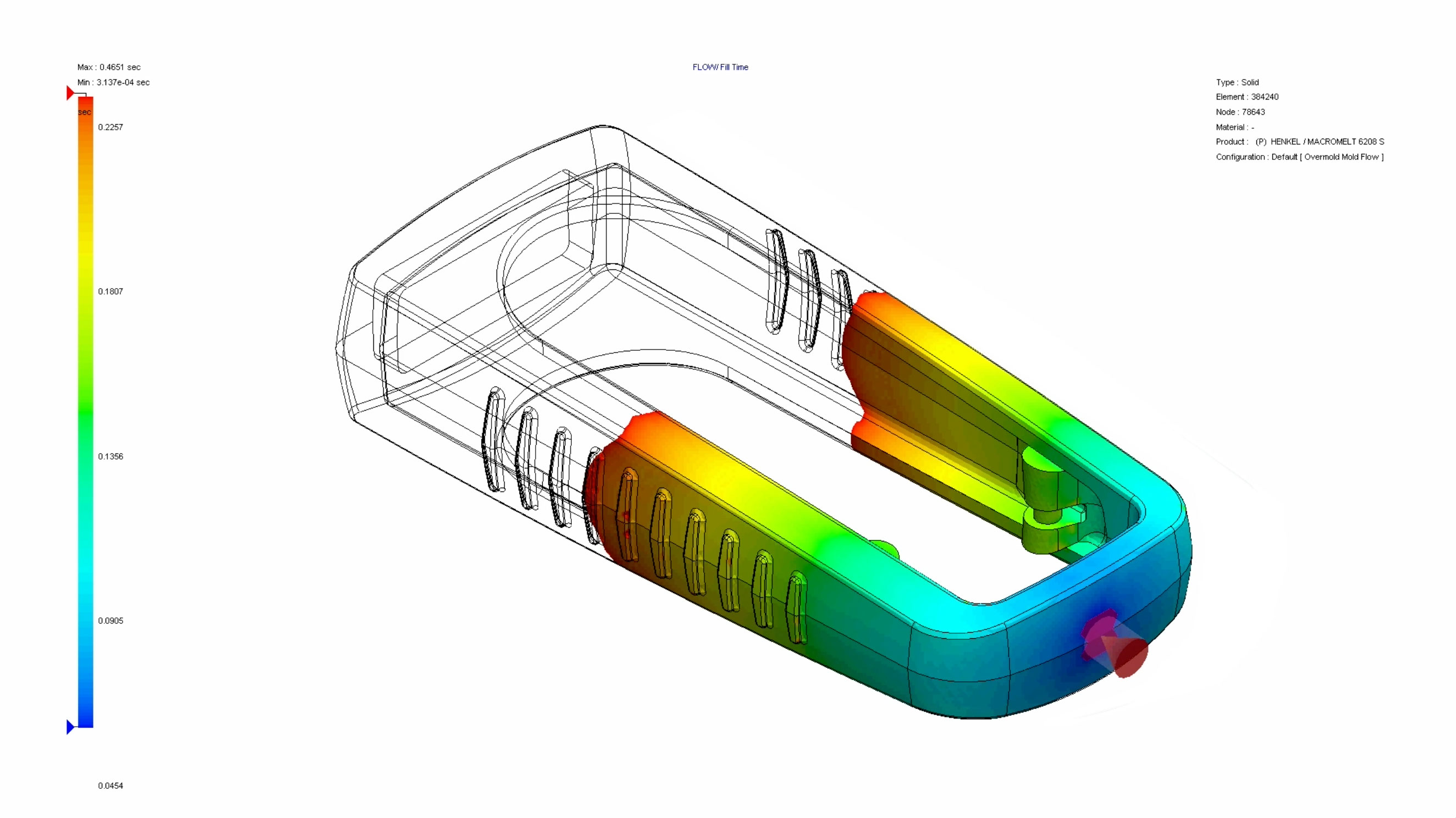

Moldflow Analysis:

2-Shot Overmolding [ Shot 2 ]

The second step of the Cavist 2-Shot Overmolding process uses high pressure injection molding, which alone would destroy sensitive electronics with heat and pressure, as a second shot of material surrounding the protected component. This allows materials of multiple hardnesses and protective qualities to surround the component for additional protection appropriate for each application.

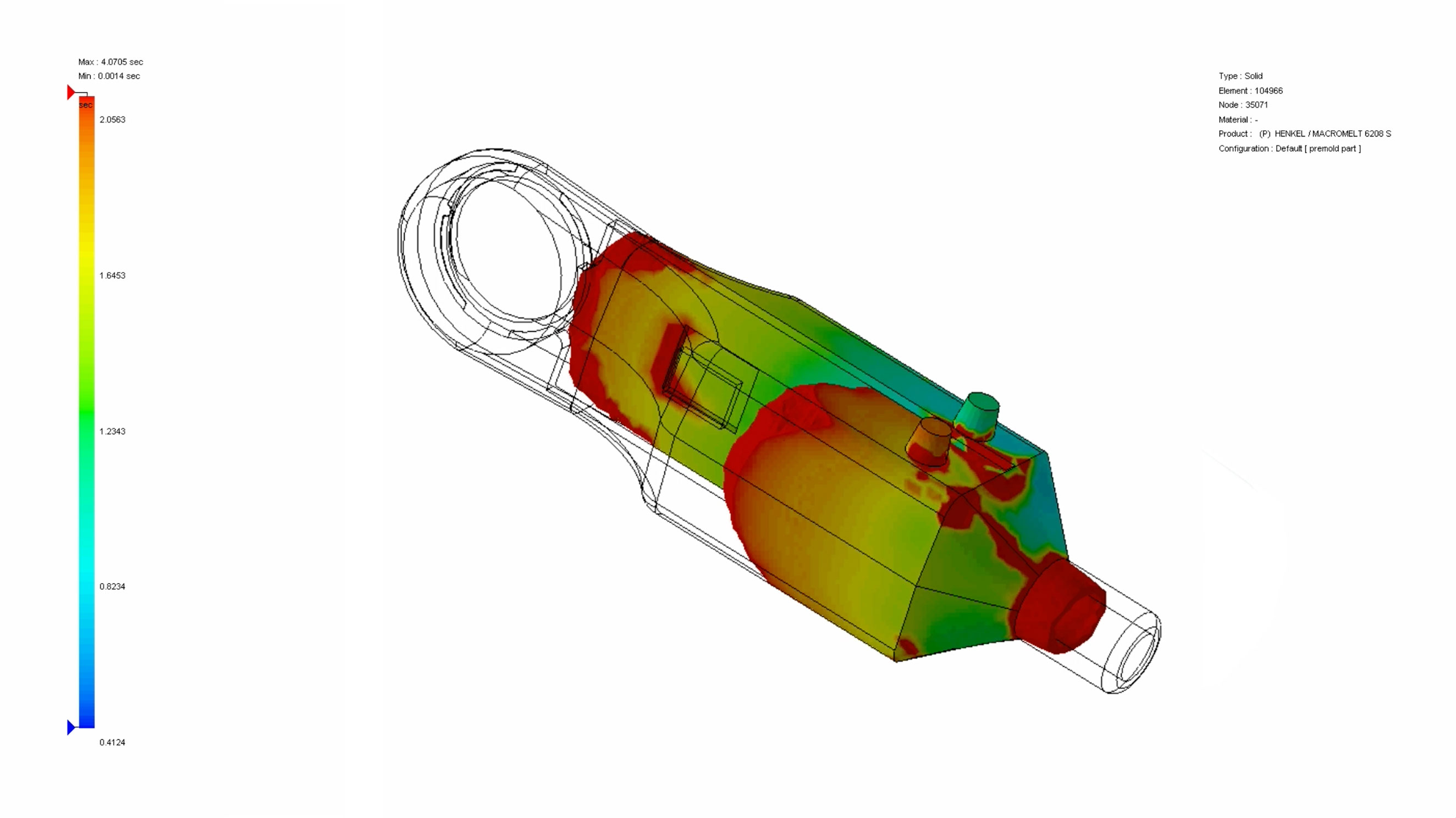

Moldflow Analysis:

Cable Overmolding [ Premold ]

This Cable Assembly premold Moldflow analysis, for Automotive parts, shows the flow of Technomelt™ Polyamide Low Pressure Molding material as it enters the cavity, flows gently around the printed circuit board (PCB) assembly, wires and cable jacket, effectively sealing while providing molded on strain relief.