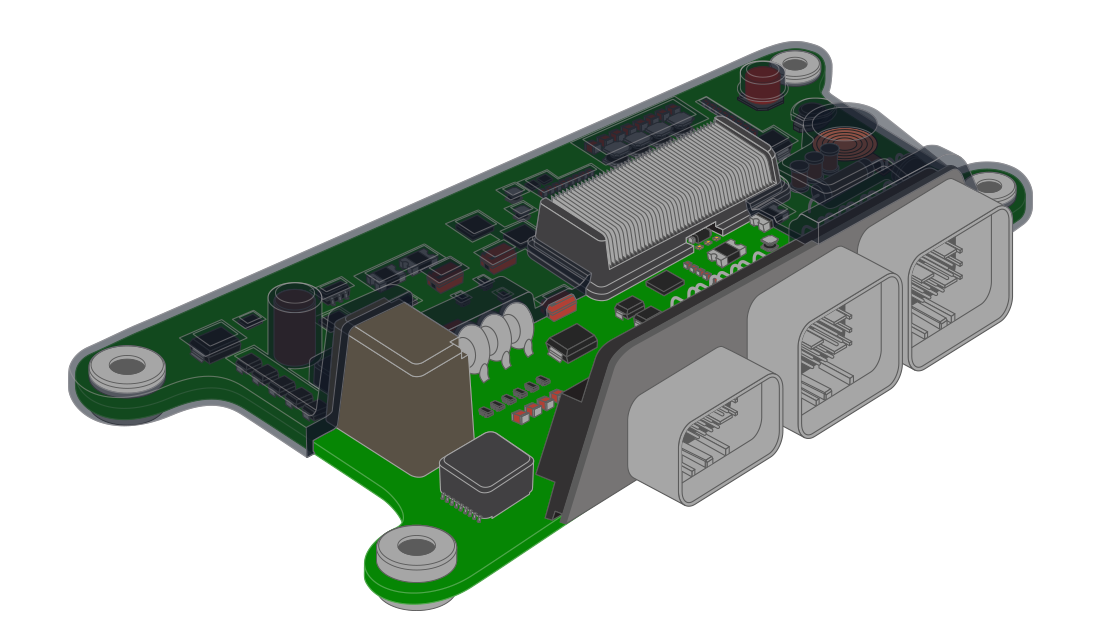

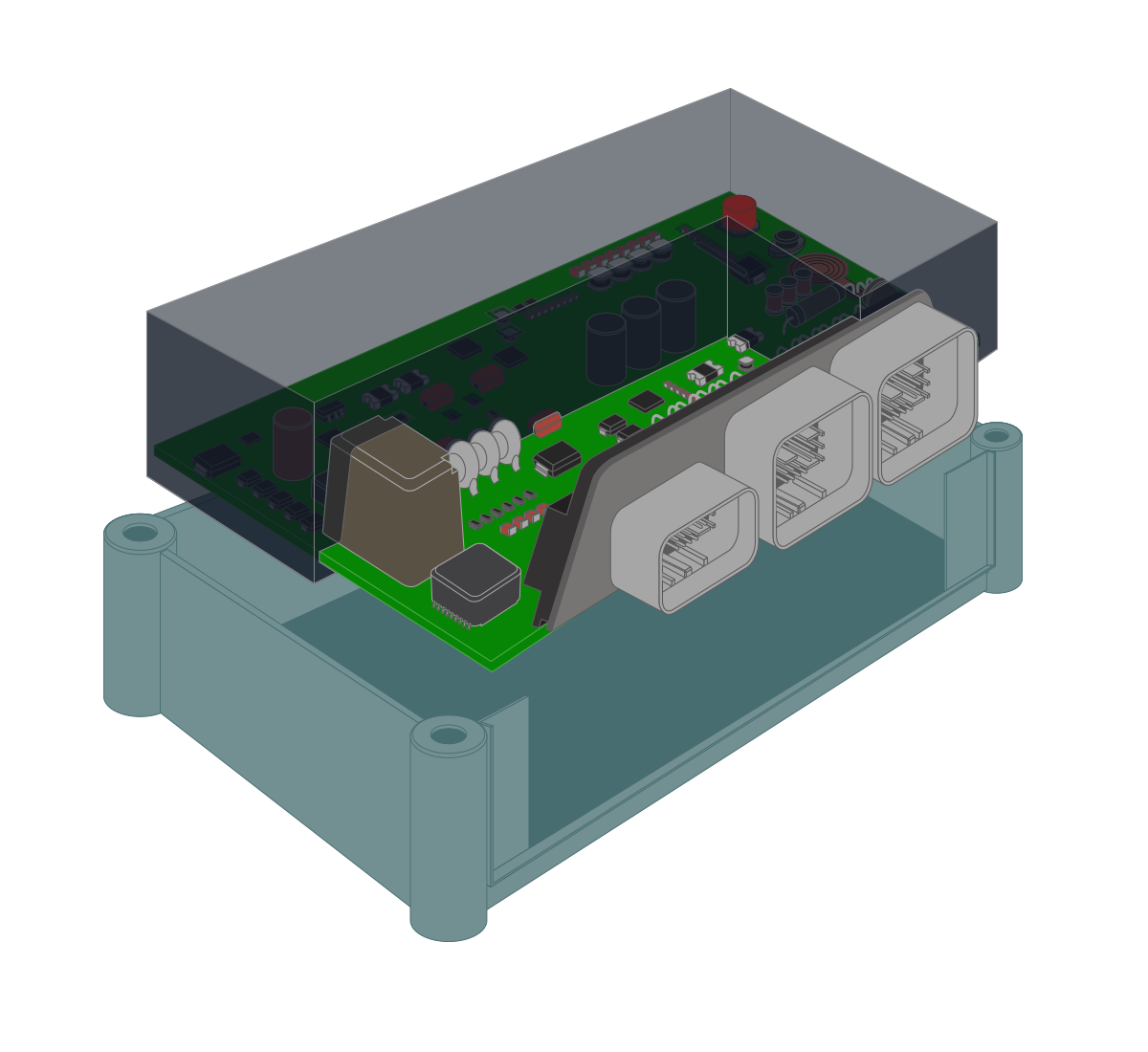

What is Epoxy Overmolding?

Epoxy Overmolding is a scaleable, single material, in-line injection molding process for high-volume applications. This new manufacturing approach offers the performance benefits of epoxy materials, yielding super-rigid, thinly-molded electronics with superior abrasion and chemical resistance, high temperature resistance, high thermal conductivity, and more.