Overmolding, the Game-changer

Overmolding continues to be a game-changer for automotive OEMs, offering far more than just mechanical reinforcement. Beyond its well-known benefits, overmolding plays a critical role in thermal management, chemical resistance, cost efficiency, and sustainability—all essential factors in modern vehicle design.

This article takes a further dive into the additional advantages of overmolding, including its ability to dissipate heat in high-performance electronics, protect components from harsh chemicals, streamline manufacturing, and support eco-friendly initiatives. These innovations not only enhance component longevity and performance but also drive cost savings and environmental responsibility.

Thermal Management & Heat Dissipation

Certain overmolding materials, aid in heat dissipation, which is crucial for power electronics and high-performance automotive components. Effective heat management is essential in applications like inverters, battery management systems, and ECUs, reducing overheating risks and improving overall efficiency. For more on epoxy molding compounds in automotive applications.

See more on Epoxy Molding Compounds

Protection Against Chemical Exposure

Automotive electronics often come into contact with harsh chemicals such as fuel, oils, coolants, and de-icing agents. Overmolding provides a chemical-resistant barrier that prevents corrosion and degradation, extending the lifespan of sensitive components and ensuring consistent performance.

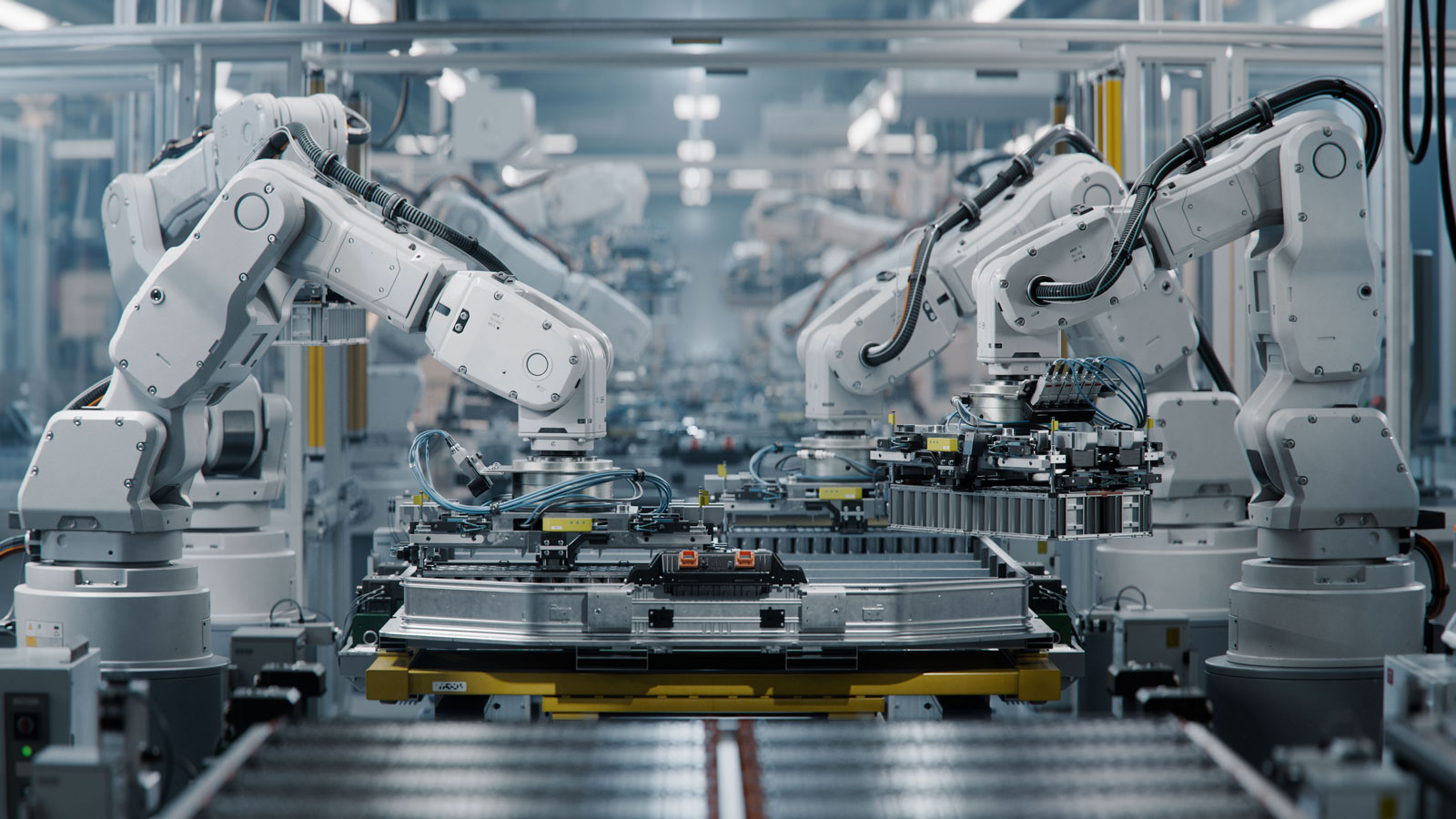

Cost Savings - Simplified Assembly and Reduced Parts Count

By integrating multiple components into a single overmolded unit, OEMs can reduce the number of parts and assembly steps required. This translates to lower manufacturing costs, faster production times, and fewer potential failure points, enhancing overall quality control.

Sustainable and Eco-Friendly Material Options

With increasing emphasis on sustainability, OEMs can leverage eco-friendly overmolding materials that are recyclable, biodegradable, or derived from renewable sources. This supports corporate sustainability goals and reduces the environmental impact of automotive manufacturing.

Conclusion

Overmolding electronics presents automotive OEMs with a transformative approach to enhancing the durability, performance, and reliability of their electronic components. By providing robust protection against environmental factors and mechanical stresses, these processes significantly reduce the likelihood of electronic failures, leading to cost savings and improved customer satisfaction. Our commitment to ISO 9001 and ISO 13485 standards guarantees precision, consistency, and reliability in every product we deliver.

Reach out to Cavist to get more information about overmolding and encapsulation.