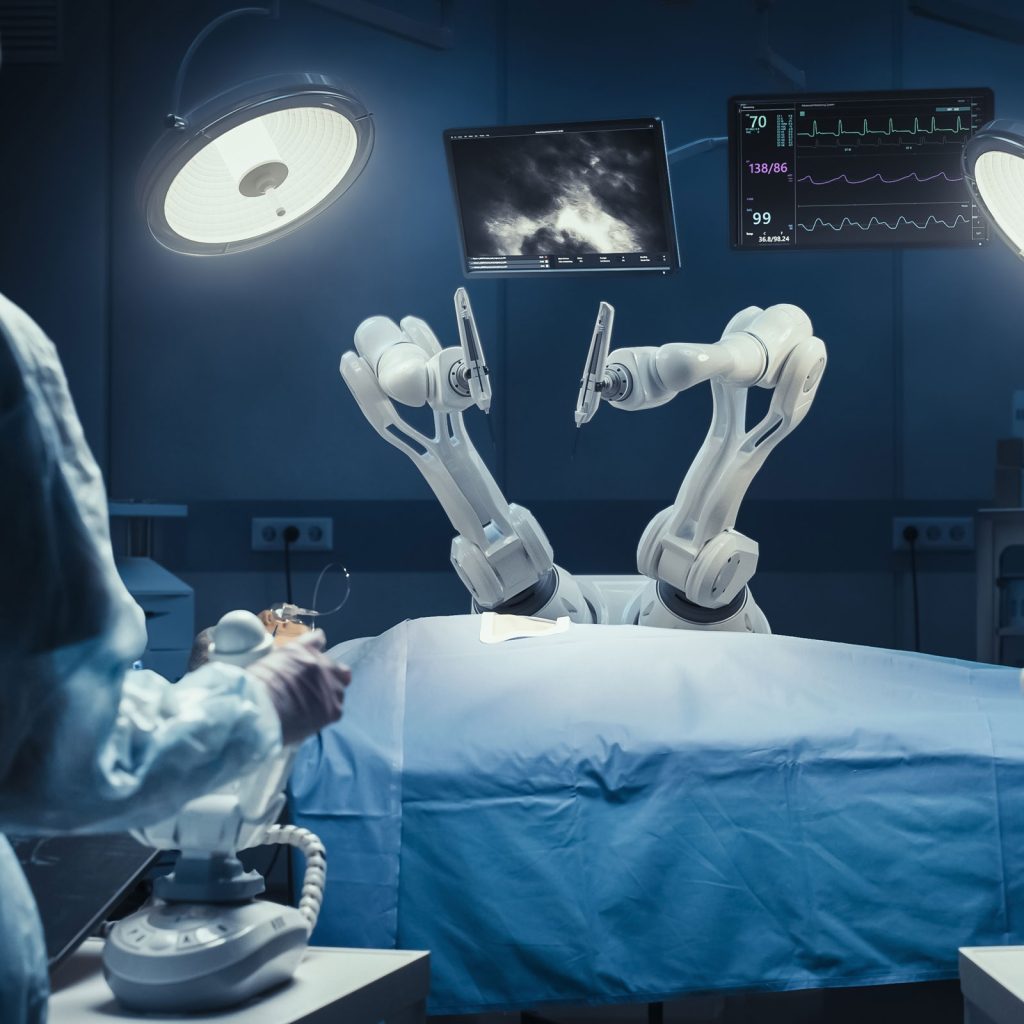

Durability & Reliability

In the surgical robotics industry, durability and reliability are non-negotiable. Surgical instruments and robotic systems are expected to perform flawlessly under extreme conditions like repetitive motion, exposure to bodily fluids, and repeated sterilization cycles. OEMs rely on sensors, cable assemblies, and electronics to withstand harsh sterilization processes. Low Pressure Molding (LPM) offers biocompatible, hermetically sealed, and mechanically reinforced encapsulation that protects sensitive components without adding too much weight or complexity.

What is Low Pressure Molding (LPM)?

Low pressure molding (LPM) involves encapsulating electronics like PCBAs, or cable assemblies using thermoplastic materials or epoxy molded compounds. LPM uses a low-temperature and low-pressure process to create a seamless, durable barrier that outperforms traditional potting or clamshell housings. Learn more about Low Pressure Molding

The Hidden Powers of Overmolding

What makes overmolding such a powerful tool in surgical device design isn’t just its ability to encapsulate sensitive electronics, it’s how it transforms the performance, durability, and usability of the instrument as a whole. Through Low Pressure Molding (LPM), overmolding delivers a precise, protective seal without exposing components to damaging heat or pressure, making it perfectly suited for critical surgical instruments.

1. Reliable IP68 Sealing for Sterilization Resilience

Low Pressure Molding (LPM) offers robust, IP68-rated environmental sealing—an essential feature for surgical instruments that must endure rigorous sterilization and cleaning protocols without compromising performance. The overmolding process encapsulates delicate electronics with a protective barrier that guards against moisture ingress, particle contamination, and mechanical stress. This makes overmolded assemblies highly resistant to moisture and bodily fluids, preventing fluid penetration during surgical use and cleaning, and protecting internal electronics from corrosion or short-circuiting. They also withstand repeated exposure to high-temperature autoclave cycles, ethylene oxide (ETO) gas, and gamma radiation without degradation or delamination.

By delivering a hermetically sealed, durable finish, LPM ensures that embedded electronics continue to function reliably through repeated use, handling, and sterilization, making it ideal for surgical tools.

2. Strain Relief on cable assemblies

Robotic surgical systems require exceptional mechanical durability to withstand the precise, repetitive movements involved in minimally invasive procedures. Overmolding plays a vital role in enhancing the longevity and reliability of cable assemblies within these systems. By encapsulating cable terminations and connector interfaces, overmolding creates integrated strain relief at high-stress bend points, areas that are especially prone to flex fatigue and mechanical failure. This added reinforcement not only prevents cable disconnection during motion but also reduces the risk of internal wire breaking over time. In dynamic environments where consistent signal integrity and power delivery are critical, overmolded strain relief helps maintain system performance, minimize maintenance, and ensure safe, uninterrupted operation throughout repeated sterilization and usage cycles.

3. Skyline Design & Light Weight

Overmolding enables the formation of a smooth, skyline-like contour across the surface of a printed circuit board assembly (PCBA). This design approach creates a slim, low-profile form factor that is ideal for surgical instruments where space is limited, and ergonomic handling is critical. By eliminating the need for bulky housings or additional fastening hardware, overmolding helps reduce the overall footprint of the device.

Additionally, the use of minimal thermoplastic or epoxy molding compound minimizes added mass, an essential factor for handheld surgical tools, where comfort and control can directly impact performance and surgeon fatigue. The result is a durable, sealed assembly that is both compact and easy to maneuver in sterile field environments.

4. Enabling Innovation Through Overmolding

As surgical instruments continue to evolve alongside advanced robotics and miniaturized electronics, the demand for components that can withstand sterilization, motion, and harsh environments only grows. Low Pressure Molding (LPM) stands out as a critical enabling technology—providing biocompatible, lightweight, and hermetically sealed protection for the electronics that power modern surgical tools. From delivering IP68-rated sealing to integrating strain relief and enabling sleek, low-profile designs, overmolding addresses the exacting needs of medical device OEMs without compromising size, performance, or reliability.

The hidden power of overmolding is not just in how it protects, but in how it enables innovation, allowing engineers to design surgical instruments that are safer, more ergonomic, and ready for the rigors of real-world use.

Ready to Future-Proof Your Surgical Devices?

Partner with a team that understands the demands of medical grade overmolding. At Cavist, we specialize in overmolding and encapsulation solutions that meet the highest standards of performance, durability, and sterilization resilience. Contact us today to explore how our capabilities can elevate your next surgical or robotic device.

Reach out to Cavist to get more information about overmolding and encapsulation.