The Future is Electronic

As a result, the world is producing the biggest array of electrical components in history. Parts like sensors, actuators, CPUs, and PCBs all need protection against damaging environmental factors like dirt, moisture, heat, and chemical exposure. Electronic encapsulation is a transformative packaging technique that protects electronics from these issues while making the manufacturing world more efficient and sustainable. From electrical vehicles to numerous other industrial and consumer applications, electronic encapsulation is the best performing solution for protecting sensitive electrical parts and turning them into resilient components.

What is Electronic Encapsulation?

Electronic encapsulation refers to a variety of manufacturing processes that are employed to protect sensitive electrical components. This is achieved through creating a casing or coating, usually with a thin layer of material that acts as a rigid but flexible shield. The primary objective of electronic encapsulation is to protect sensitive parts from mechanical strains and degradations caused by harsh environmental conditions. Sometimes manufacturers will use this process to color code different electronic elements. This practice is also used to prevent electronic devices from being reverse-engineered or tampered with by competitors or people seeking to access private and secure digital information.

Methods of Encapsulation

There are three methods of electronic encapsulation used in manufacturing today. These include Conformal Coating, Epoxy Potting and Overmolding.

The choice of which method should be selected is contingent upon various factors. Some of these considerations include the equipment and labor costs, production volume needed, cycle time, particular application requirements, and packaging reliability and flexibility.

Let’s look at all three.

Conformal Coating

As the name suggests, conformal coating refers to a protective, non-conductive dielectric layer that is added to cover an electronic circuit board or device. This material is applied to the surface of a substrate, conforming to the shape of the object being coated without making a significant difference in the weight or thickness of the component.

Conformal coating is a popular choice for PCBs and it does offer some benefits. It is often the cheapest option for protecting electronics. Additionally, it has a simple application process. Conformal coatings are electrically insulating and maintain long-term surface insulation resistance. They are also an effective barrier to air-borne contaminants that can cause corrosion.

Some disadvantages of conformal coating are inherent in the coating itself. It is an incredibly thin and translucent material. Because of this, it does not offer a high level of durability or resilience. While the coating does add a layer of moisture resistance, it cannot be considered waterproof. The material is also rigid, providing less flexibility of the component. There are limited applications in electronics because conformal coating makes it difficult to use screws, spacers, and fasteners on coated areas. Additionally, some coatings contain solvents and diluents that can be harmful to the environment and people in production.

Epoxy Potting

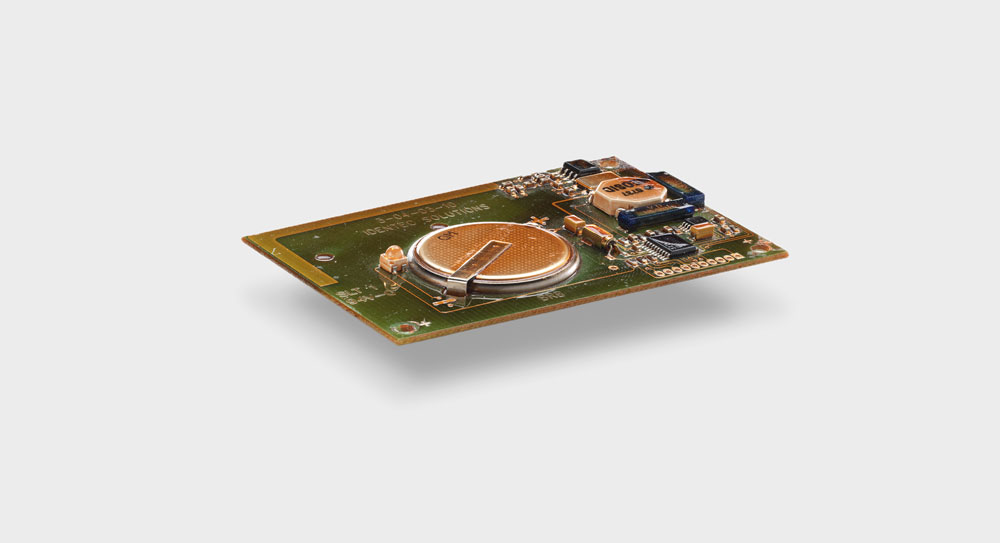

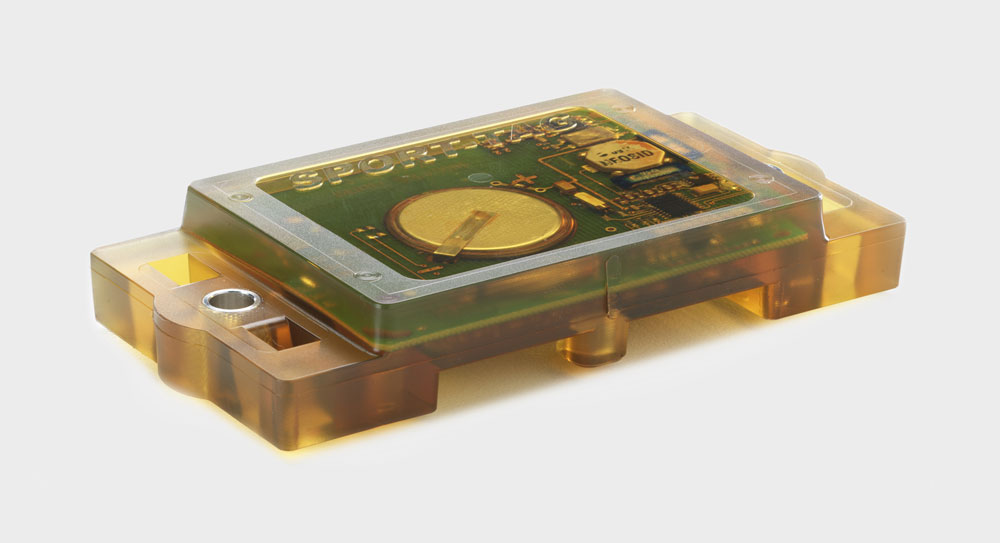

Epoxy potting, sometimes referred to as embedment, is the process of encapsulating an electronic component by using a “pot” or hard shell. This encasement is then filled with a substrate that fills the cavity and covers the electronic part entirely. The result is a hardened compound that surrounds the board or device.

Potting does offer quite a few benefits for protecting electronics. The hardshell casing is typically the strongest encapsulation method. Epoxy can withstand temperatures up to 250 degrees, making it an excellent choice for resisting extreme temperatures. Since the electronic component is embedded with strong adhesives in the pot, the component is safe from reverse engineering and tampering.

There are some significant disadvantages to using this method for encapsulation of electronics. The finished product usually endures a significant weight increase, as well as less flexibility. The curing process for epoxy potting involves significantly more time, space, steps and material than conformal coating and overmolding which equates to higher manufacturing costs and Work In Process (WIP) inefficiencies. Electronic components also have a higher increase of being damaged during this process because of the heat from the curing reaction as well as the shrinkage of potting compounds. This can damage components and solder bonds.

Overmolding

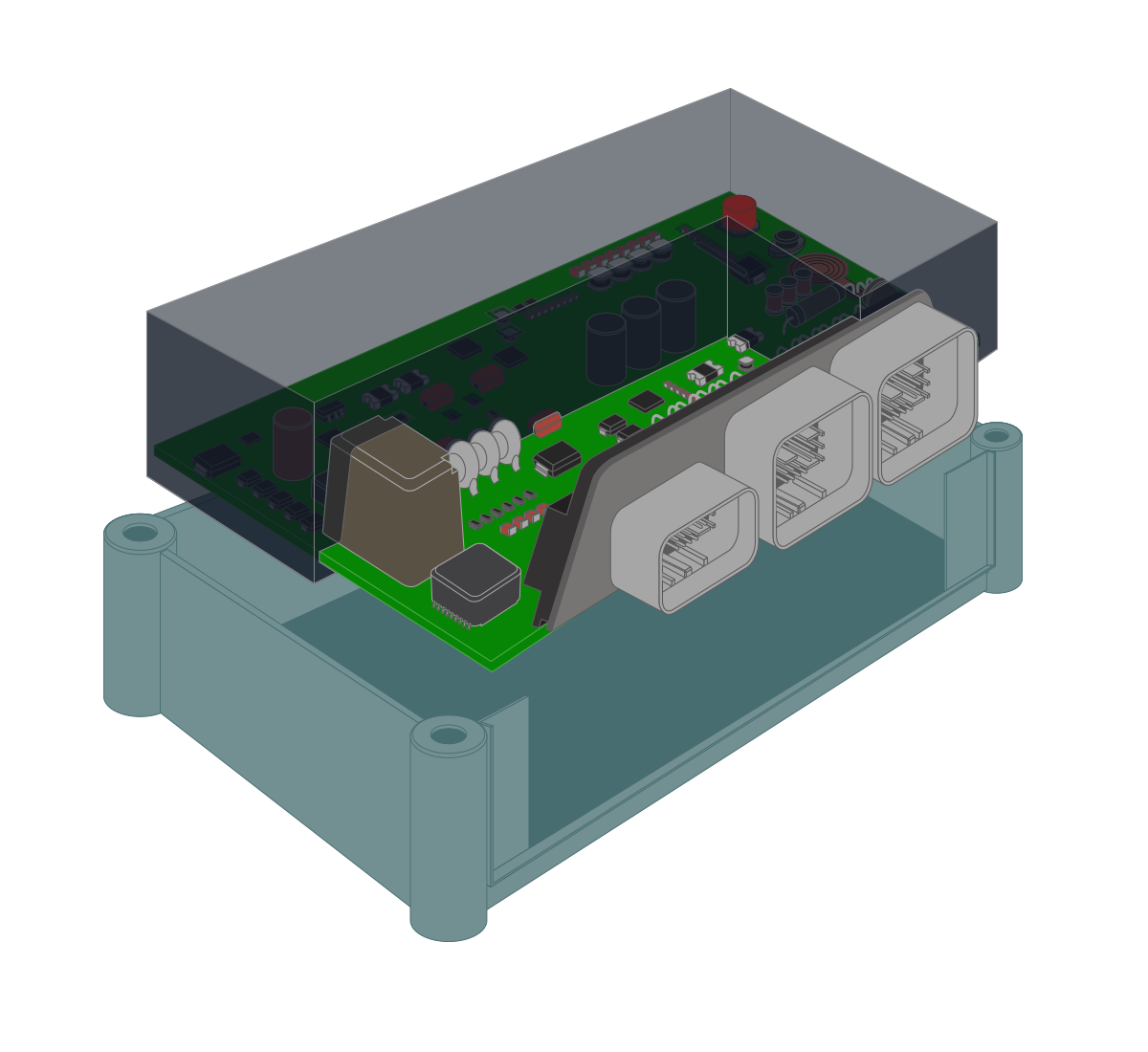

Overmolding is a low-pressure and low-temperature injection molding process that uses various thermoplastic materials with very low viscosity to overmold and protect and encapsulate electronic parts. The material used for overmolding is typically a thermoplastic like polyamide or other traditional elastomers (TPE). During the overmolding process, the material is melted and injected into a mold that is designed to fit the circuit board or electronic device. The plastic quickly cures, allowing the component or device to be removed quickly. Other benefits of electronic encapsulation via overmolding include better durability and protection from mechanical strains, impacts, and vibrations than conformal coating and epoxy potting. The overmolding process also offers enhanced moisture resistance and improved electrical performance.

In the last few years, Cavist has successfully overmolded electronics using Epoxy Molding Compounds (EMC). The EMCs provide the same encapsulation benefits as seen in epoxy potting, but the epoxy overmolding process does not have any of the weight and batch process limitation.

See Low Pressure Molding, 2-Shot Overmolding and Epoxy Overmolding.

Cavist is Ready to Encapsulate Your Electronics

Electronic Encapsulation offers numerous benefits for manufacturing electronic devices in every type of market. The strengthened ability to withstand harsh environmental factors is coupled with additional protective features that extend the lifetime of electronic devices and help protect the environment with sustainable manufacturing. Cavist is the subject matter expert in overmolding and electronic encapsulation. With over 30 years of experience, we offer a range of overmolding techniques.

Reach out to Cavist about Electronic Encapsulation.