When injection molding over live electronic circuitry, heat and thermal considerations play a major role in the tooling design and approach. Our customers often inquire, “if you inject plastic at 420°F, and lead-free solder melts at about the same temperature, how can you ensure you’re not doing damage to the electronics?” The answer to the question lies in the way we actively control the dissipation of heat into the tooling.

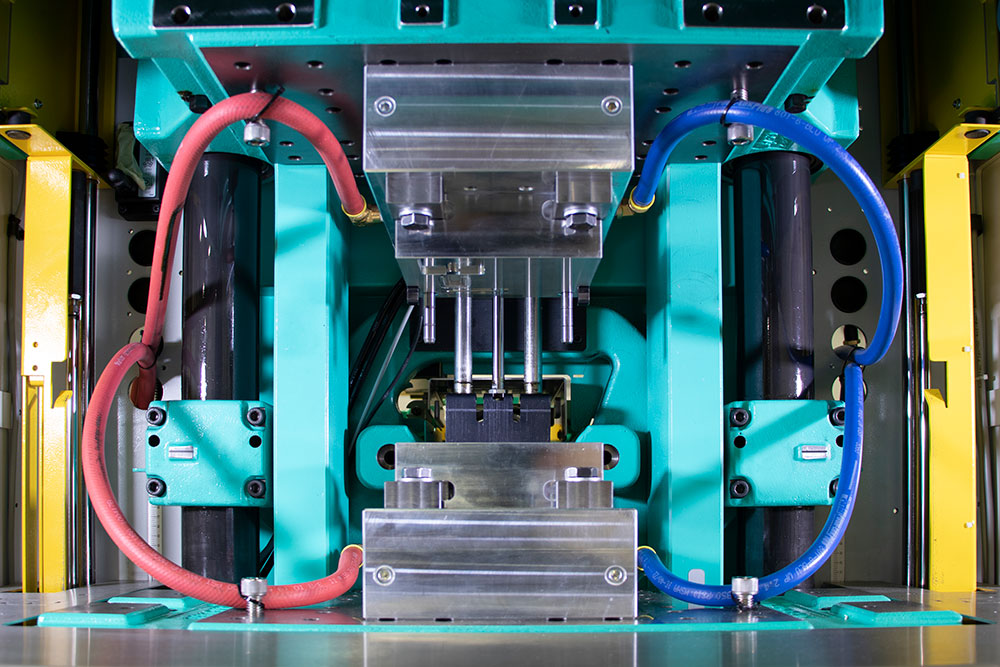

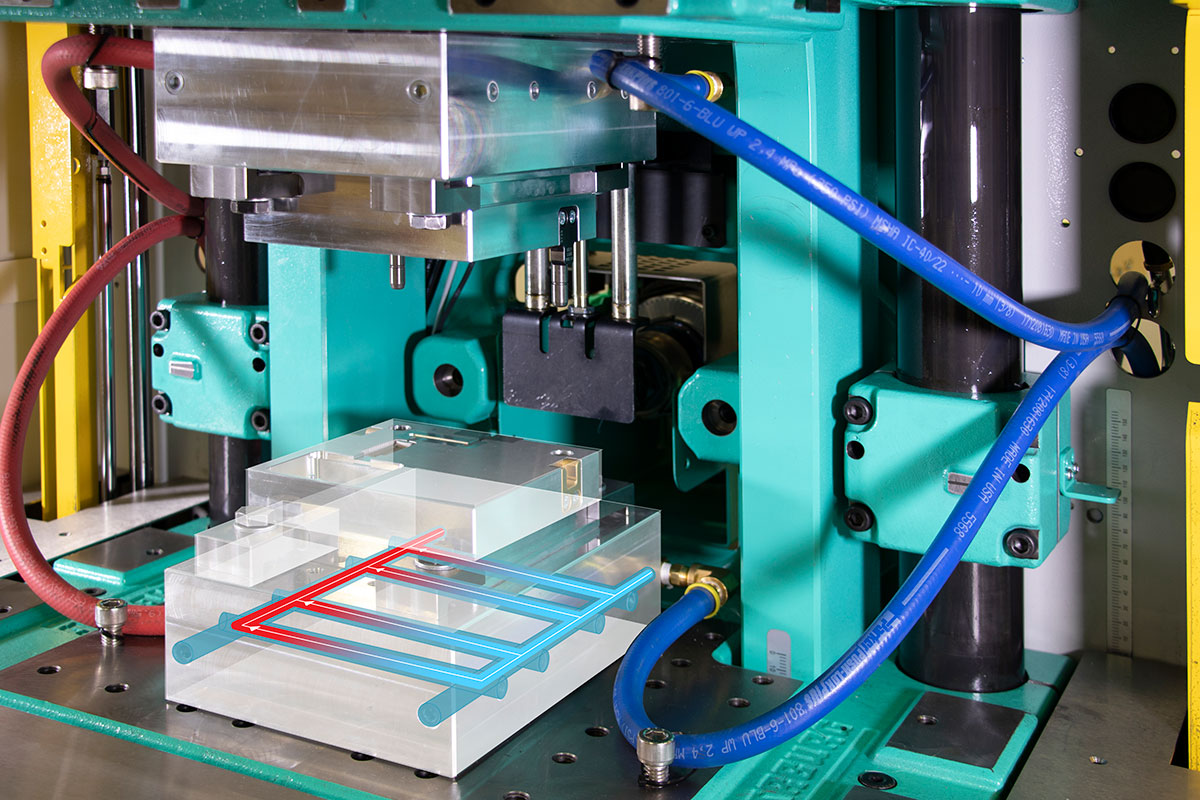

Each of the tools we design for low pressure molding comes with a plan for moving heat rapidly away from the device that is being overmolded. For most applications, a liquid-cooled, aluminum moldset is more than adequate to drive the heat away from the electronics. Aluminum is an excellent conductor of heat. When molding material is injected, heat is dissipated into the runner system and walls of the tool cavity. A chiller circulates a working fluid through the moldset to help maintain a consistent tool temperature. This is key to developing a stable manufacturing process for low pressure molding.

Of course, the electronics themselves will absorb some amount of heat through the process, so it is important to limit the exposure to a safe level to avoid damage to critical components. In most cases, we can limit the temperature spike to an increase of ~100 degrees for around 5-10 seconds, after which the electronics slowly cool back to room temperature within a few minutes.

There are applications that require a more sophisticated approach to managing the thermal loading during the overmold process. Products that include batteries or temperature sensitive ICs require a closer look during the tooling design phase. Batteries can be quite sensitive to high temperature spikes, and the overmolding process can pose a risk if it is not done correctly. Exposing most batteries to elevated temperature, for even a small period of time, will shorten the lifetime of the battery significantly. Some battery chemistries have electrolyte solutions that can boil if exposed to temperatures of 180°F and higher. For this reason, we must pay very careful attention to how we gate in the overmold cavity and where we choose to dissipate the heat into the moldset. To date, we have not come across a battery that we could not overmold successfully.