Articles about Overmolding Electronics

Written by Cavist, the pioneers of low pressure molding technology in the US.

Overmolding continues to be a game-changer for automotive OEMs, offering far more than just mechanical reinforcement...

Read More

Overmolding continues to be a game-changer for automotive OEMs, offering far more than just mechanical reinforcement...

Read More

In a rapidly evolving automotive industry, Original Equipment Manufacturers (OEMs) are constantly seeking innovative solutions to enhance...

Read More

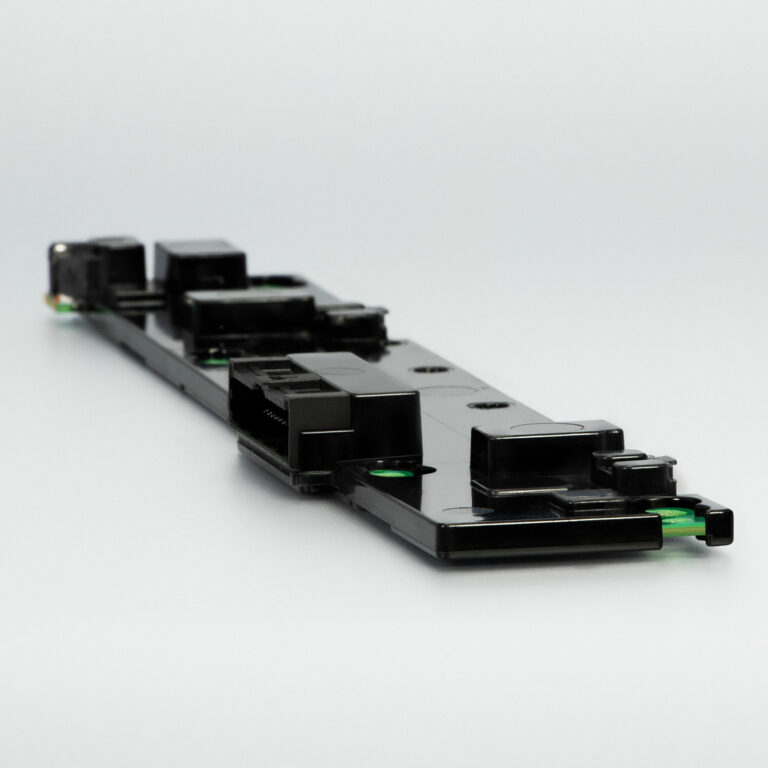

Electronics are an integral part of modern life, powering countless applications such as medical devices, automotive systems, and consumer gadgets...

Read More

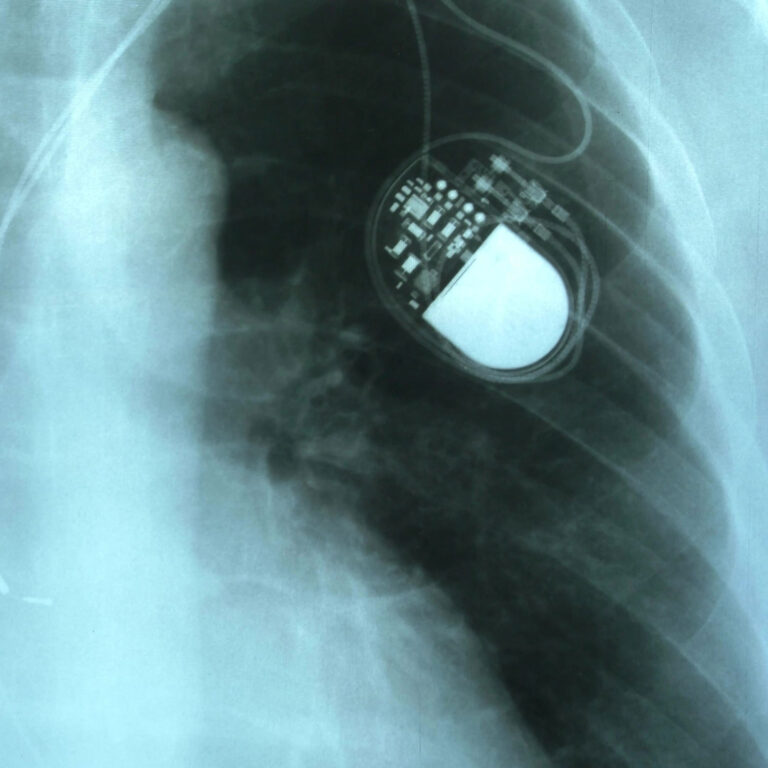

The incorporation of electronics into medical devices began in earnest in the mid-20th century, with transformative innovations such as the implantable pacemaker...

Read More

Ingress Protection (IP) ratings play a crucial role in evaluating the robustness and longevity of electronic devices by measuring their resistance to...

Read More

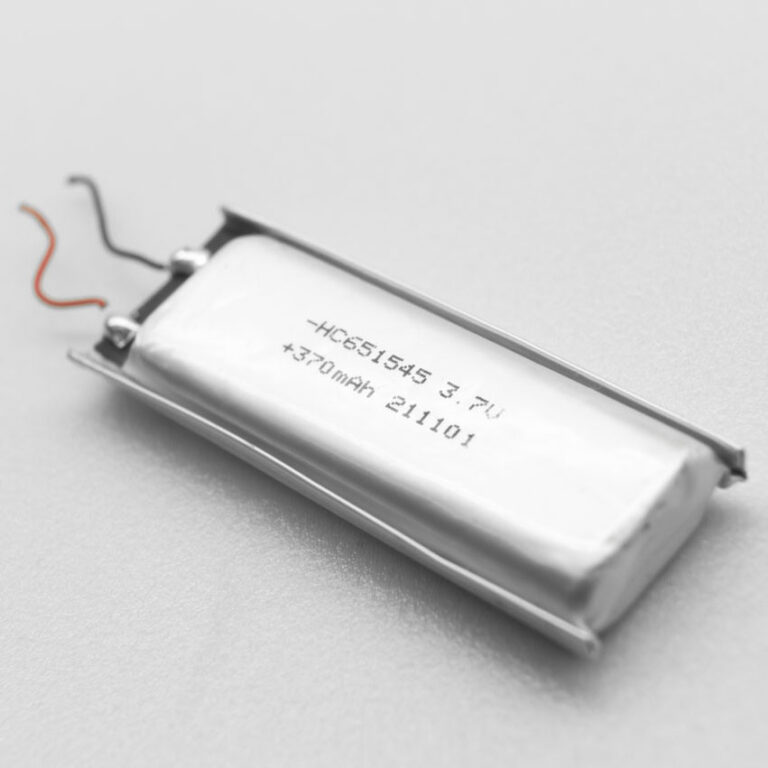

With the surge in battery-powered electronics, the need for advanced protection methods has become more critical than ever...

Read More

The rise of wearable technology has significantly transformed the daily lives of many by embedding advanced electronics into accessories...

Read More

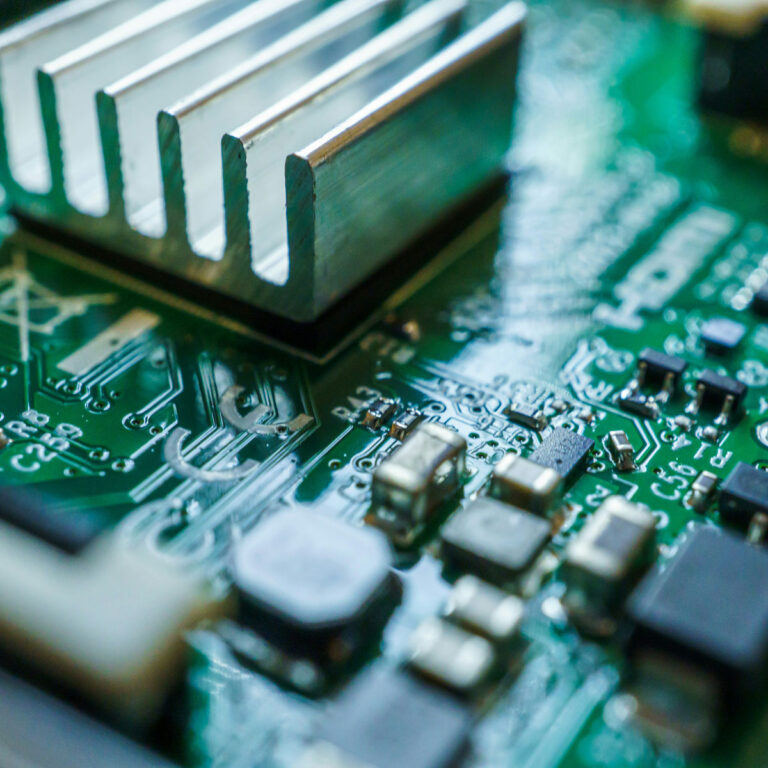

The Future is Electronic. As a result, the world is producing the biggest array of electrical components in history. Parts like sensors, actuators, CPUs, and PCBs all...

Read More

As the automotive market continues to shift toward electrification, Cavist sees increasing promise for the application of Epoxy Molding Compounds (EMCs) for PCB-level electronic...

Read More

When it comes to protecting electronics from harsh environments, design engineers have only a limited number of technologies to choose from...

Read More

Function vs. Aesthetics The look and feel of a molded product is important, but with LPM it is rarely the driving factor in a design. Engineers seek a molded electronic device...

Read More

As mentioned elsewhere, it makes sense to consider a two-step overmolding approach in several situations: If the electronic assembly must be completely sealed If the positioning...

Read More

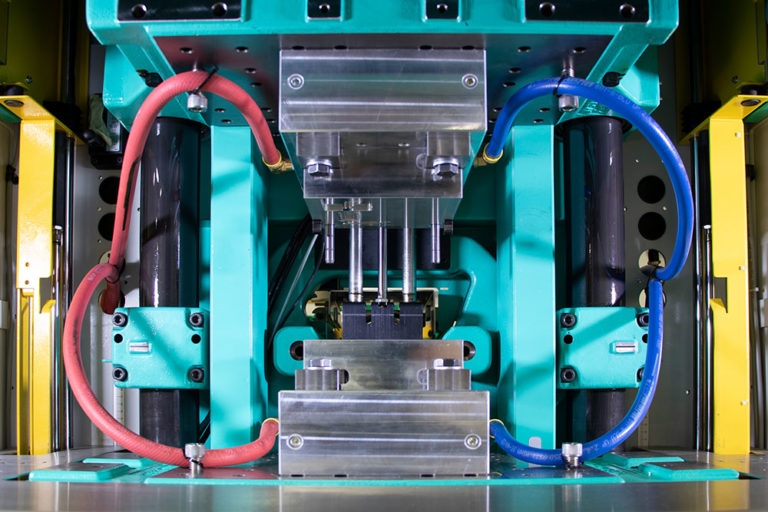

When injection molding over live electronic circuitry, heat and thermal considerations play a major role in the tooling design and approach. Our customers often ...

Read More

Customers frequently ask us how to design a part for low pressure molding (LPM). Over the years, Cavist has built a comprehensive set of guidelines we utilize to ensure our...

Read More