Epoxy Molding Compounds for Auto/EV Applications

As the automotive market continues to shift toward electrification, Cavist sees increasing promise for the application of Epoxy Molding Compounds (EMCs) for PCB-level electronic packaging solutions…

Epoxy Overmolding : A new approach to proven protection

When it comes to protecting electronics from harsh environments, design engineers have only a limited number of technologies to choose from…

Tips and Ideas for LPM Designers

Function vs. Aesthetics The look and feel of a molded product is important, but with LPM it is rarely the driving factor in a design. Engineers seek a molded electronic device that can pass testing and withstand harsh environments. While aesthetic appeal may not be critical to the product design, many of our customers do […]

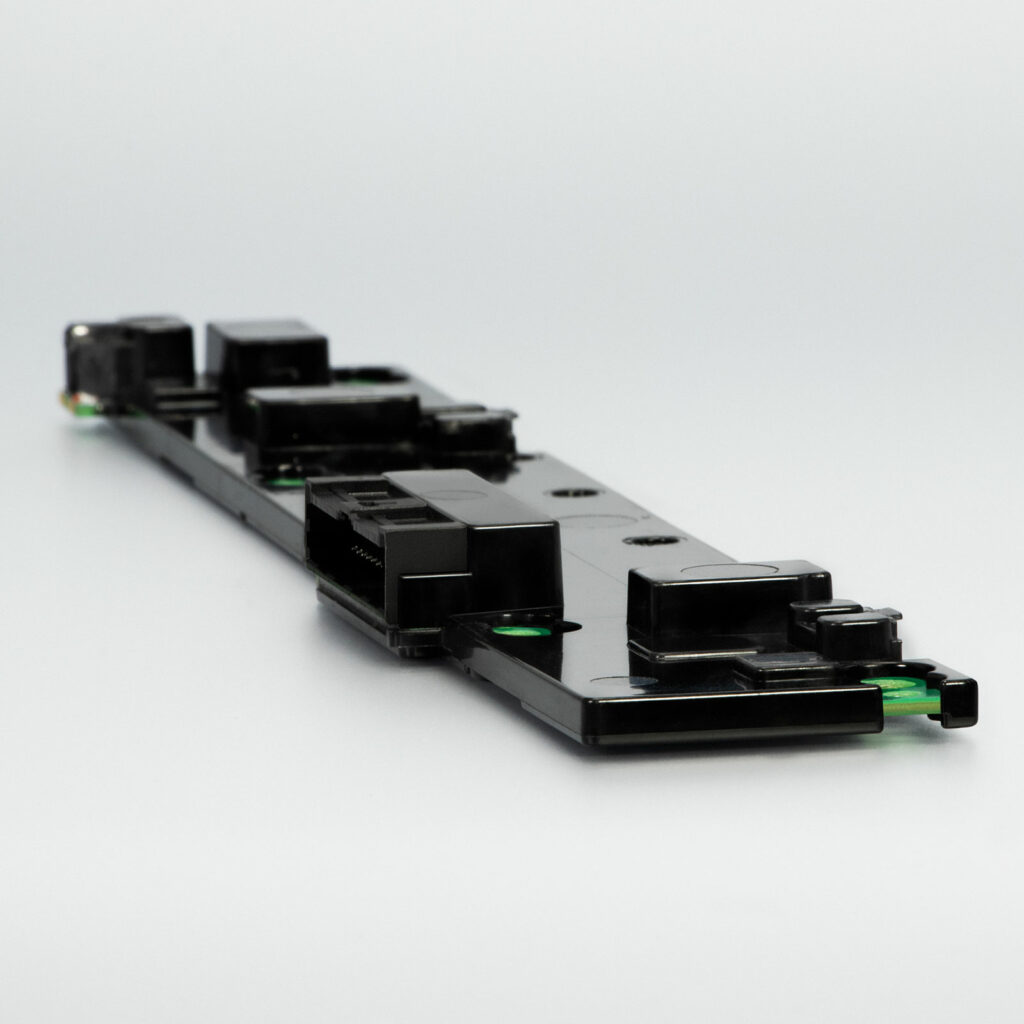

Overmolding Electronics : Premold Design

As mentioned elsewhere, it makes sense to consider a two-step overmolding approach in several situations: If the electronic assembly must be completely sealed If the positioning of the electronic package inside the final overmold is critical (sensor, antenna or Bluetooth chip locations may dictate accurate location) If the project requires light pipes, we will typically […]

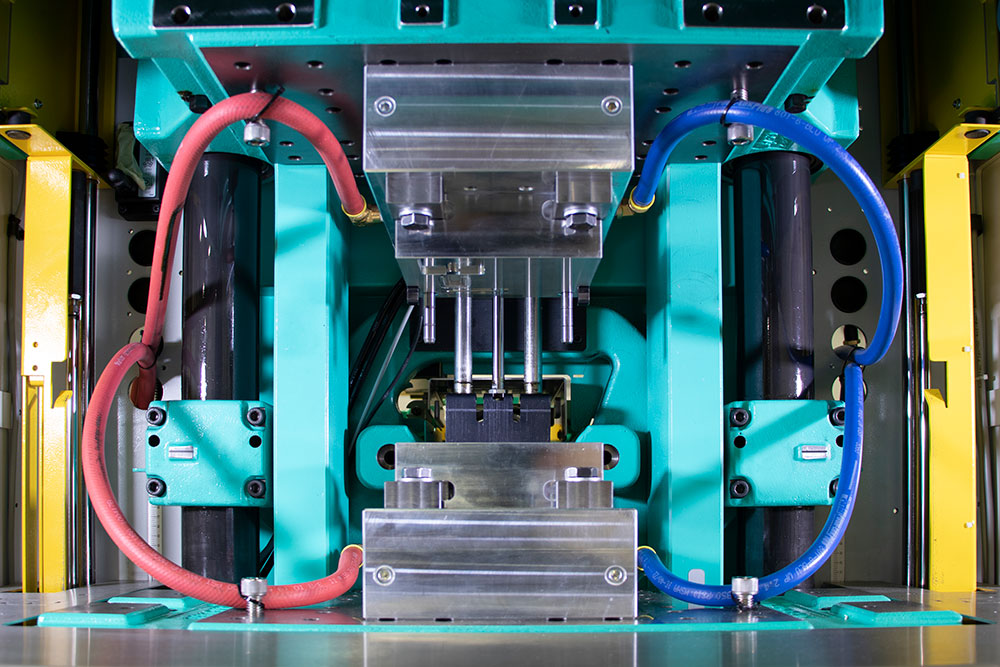

Thermal Concerns When Overmolding Electronics

When injection molding over live electronic circuitry, heat and thermal considerations play a major role in the tooling design and approach. Our customers often …

Basic Design for Low Pressure Molding

Customers frequently ask us how to design a part for low pressure molding (LPM). Over the years, Cavist has built a comprehensive set of guidelines we utilize to ensure our success. Most of this knowledge was derived from years upon years of making mistakes, but looking back there is some common sense that is involved. […]